GREENBAFx: Success of a pilot facility at the Waelzholz works

EBNER Industrieofenbau | Peter Seemann, Senior Principal Technology Expert | Andreas Sauschlager, Senior Principal Technology Expert

GREENBAFx

Success of a pilot facility at the Waelzholz works.

The demands placed on modern manufacturing processes are extremely diverse: industries require processes that are energy efficient, reduce carbon emissions, are highly automated and are cost effective. With the development of the recently-introduced GREENBAFx® line of bell annealer facilities, EBNER has marked another milestone in the field of sustainable heat treatment. This innovative technology combines extremely high energy efficiency with zero emissions and fully-automated processes, blending environmental responsibility with financial benefits.

EFFICIENT AND SUSTAINABLE HEAT TREATMENT: A NEW APPROACH

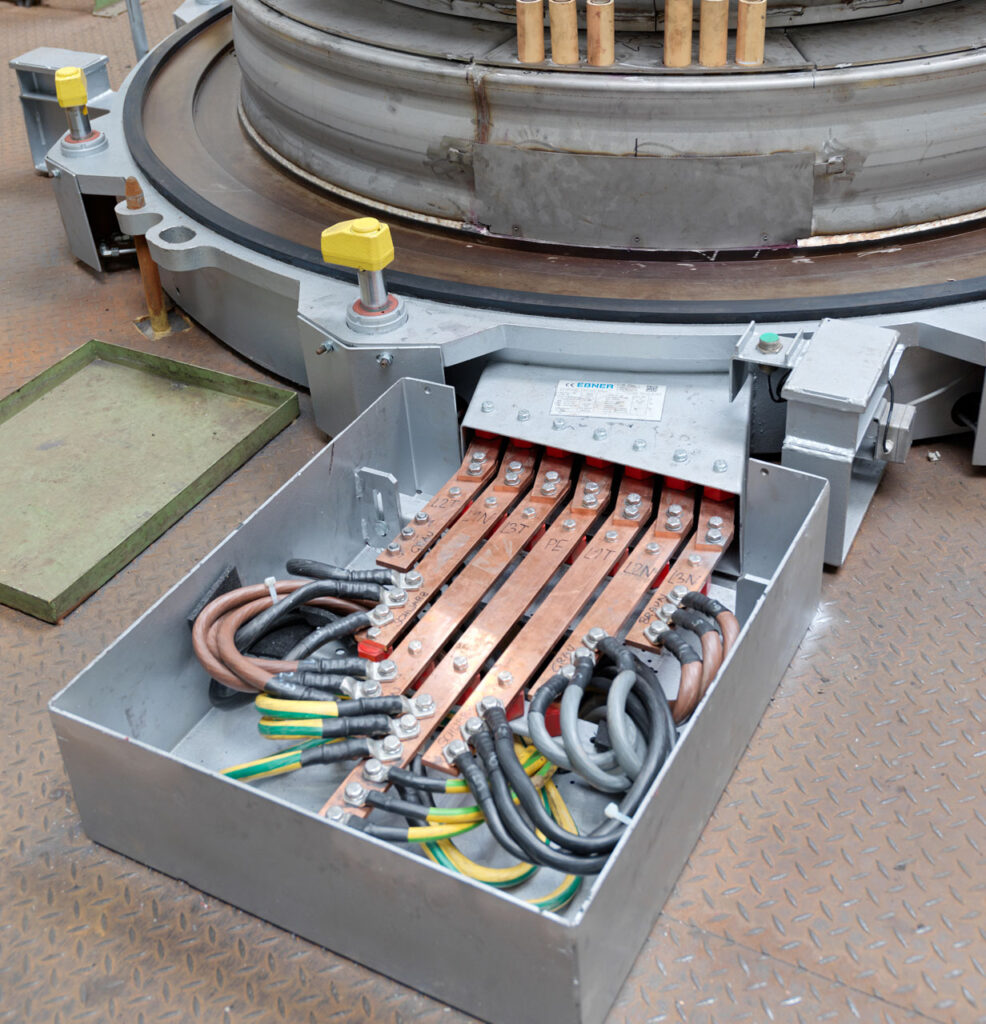

GREENBAFx® stands out due to its high energy efficiency and its zero-emission heat treatment process. Integration of the heating system into the workbase and the direct transfer of thermal energy minimize heat losses, while an innovative energy exchange system uses the energy released during the cooling process to preheat another charge. The use of a single “process” bell, which combines the functions of a heating bell, cooling bell and inner cover, greatly simplifies operations. This design significantly reduces the required number of interventions and crane movement cycles, as well as waiting times. The reduction of thermal stresses extends the service lives of components, and the wide variety of cooling options allows flexible production without sacrificing quality. In addition to all this, GREENBAFx® allows thermal energy to be efficiently recovered. A hybrid heating system (gas/electric) is available as an option, and existing facilities can be easily upgraded.

GREENBAFx®: TWO OPTIONS TO MAXIMIZE SUSTAINABILITY

To optimally fulfill the widely differing needs encountered throughout the industry, GREENBAFx® is available in two design variants. Both variants are intended to significantly reduce energy consumption and emissions, but differ in how they use and recover thermal energy.

THE “BASIC” CASE: DIRECT ELECTRIC HEATING

- High-performance heating system, integrated into the workbase diffuser

- No need to exchange bells; only two crane movements are needed per annealing cycle

- Fully-automated process sequence using a process bell

- Alternatively, hybrid operation with a heating bell (gas/electric heating) is possible

- Due to the reduction of heat losses, savings of up to 5 % in net energy consumption can be achieved

- Zero emissions: no CO2 or NOx is emitted

THE “ADVANCED” CASE: THERMAL ENERGY RECOVERY THROUGH HEAT EXCHANGE

- Use of the energy released during cooling to preheat a neighboring coil stack

- Up to 30 % of the energy fed into the system can be recovered

- Fully-automated process sequence using a process bell

- Alternatively, hybrid operation with a heating bell (gas/ electric heating) is possible

- The consumption of electrical energy by a typical 60 t charge is reduced from 178 kWh/t to 124 kWh/t (in comparison to a conventional bell annealer facility with an electric heating system)

- Improved coil quality due to reduced heating and cooling rates

By employing a GREENBAFx® facility, energy savings of up to 30 % can be achieved. This not only represents a significant reduction in electrical energy consumption, but also leads to a significant reduction in operating costs. Furthermore, this technology contributes to the sustainability of a manufacturing process, in that it significantly reduces carbon and NOx emissions. The compact design allows available space to be efficiently used, and also makes the system eminently suited for retrofitting at existing facilities. At the same time, a GREENBAFx® ensures maximum process stability and the highest product quality – environmental and financial advantages are united in a single design.

SUCCESSFUL PRACTICAL TESTS AT THE WAELZHOLZ WORKS IN HAGEN, GERMANY

Founded in 1829, Waelzholz today is an innovative and internationally-active family-owned company employing cutting-edge technology, with branches on four continents. Over 2400 employees throughout the world manufacture tailor-made steel strip and profiles – not only in Europe, but in China, North America and South America as well. As one of EBNER’s long-term customers, Waelzholz consciously chose to cooperate with EBNER on the GREENBAFx® technology project – with the goal of aggressively pushing both energy efficiency and sustainability forward.

THE ROAD TO OVER 100 SUCCESSFUL ANNEALS

The cooperation between Waelzholz and EBNER on the GREENBAFx® began when one workbase at the Waelzholz works was rebuilt in February 2024. Long term testing of the facility was then conducted under industrial conditions.

Between June 2024 and August 2025, the facility was repeatedly optimized under real production conditions. This allowed major progress to be made and performance to be significantly improved, in that annealing times were optimized and hydrogen consumption was sharply reduced. In addition to this, information was collected on the system’s durability during continuous operation, and additional improvements were made to components. August 2025 marked a significant achievement: the facility had successfully completed over 100 anneals, and nothing could stop the successful roll-out of this new technology.

Thanks to the close cooperation between EBNER and Waelzholz, GREENBAFx® is the most technologically advanced and future-oriented solution currently available, marking real progress for our industry in terms of energy efficiency and sustainability.

PROFITABILITY AND THE ENERGY REVOLUTION

Over the last few decades, bell annealer facilities have typically been heated with natural gas; this has been due to the fact that the cost of fuel gas was significantly lower than that for electrical energy. The innovative GREENBAFx® design, with its thermal energy recovery systems, eliminates most of this price difference between natural gas and electrical energy – even in regions where electrical energy is relatively expensive, such as Central Europe.

This makes a significant contribution to the energy revolution – although, in the final analysis, the transition to renewable energy will depend on the regionally-varying frameworks for energy policy.