EBNER GROUP Blog

Innovation, Technology, Sustainability and People.

Welcome to the EBNER GROUP Blog!

Let’s take a deep dive into the world of innovation, talk about sustainability and provide exciting insights behind the scenes of our international EBNER GROUP. Find out more about our latest technologies, projects and success stories – from groundbreaking developments in the industry to the people who make them possible. Stay informed about current topics, events and news from all EBNER GROUP companies.

Latest News

Christopher Lichtenegger on global standards at EBNER

I joined EBNER in December 2021 and have since taken over as head of Corporate Quality Management. My focus is on the further development and global harmonization of our quality standards. Trust-based cooperation and a working environment in which collaboration and further development are actively practiced are particularly important to me.

EBNER Software Excellence

In the world of industrial furnaces, a new revolution is underway. While hardware remains essential, the true power of a furnace now lies in its software. Furnaces today are no longer standalone products — they are intelligent, connected systems that rely on software for performance, efficiency, and long-term reliability.

EBNER Engineering

The EBNER Engineering Department is the heart of our company, combining decades of experience with concentrated engineering expertise. Our design team brings around 4000 years of collective experience to the development of advanced heat treatment facilities designed for extreme thermal requirements. We specialize in designing and implementing tailor-made solutions – from the initial idea all the way through to the creation of detailed manufacturing drawings.

Driving Green Technologies

Responsibility for the future. With our sustainable solutions, we are driving decarbonization in the industry.

Zero-emission heat treatment

Decarbonizing the steel industry is essential – especially energy-intensive processes like heat treatment. In this interview, Sascha Eppensteiner explains how emission-free technologies such as electric direct heating and smart heat recovery systems, exemplified by the GREENBAFx®, contribute to climate-neutral production while remaining economically viable.

From concept to reality: the development of GREENBAFx®

Sustainability is no longer a trend – it’s shaping industrial innovation. With the GREENBAFx®, EBNER has developed an emission-free, energy-efficient solution that proves ecology and economy can go hand in hand. In this interview, Sascha Eppensteiner shares insights into the idea, technological challenges, and the future of green industrial processes.

Green Sapphire

Sulitjelma, a former copper mining town located within the Arctic Circle in Norway, is now the home of ARCTICSapphire. Instead of digging up ore, the town has become focused on growing sapphire crystal – a highly sought-after material with immense industrial value. By employing technologies developed in-house, ARCTICSapphire is pioneering a new chapter in sustainable crystal manufacturing.

More News

Spiking Heat Treatment

Spiking is a short and fast heat treatment process applied to solution annealed aluminum strip after quenching, creating specific mechanical properties in semi-finished or finished products.

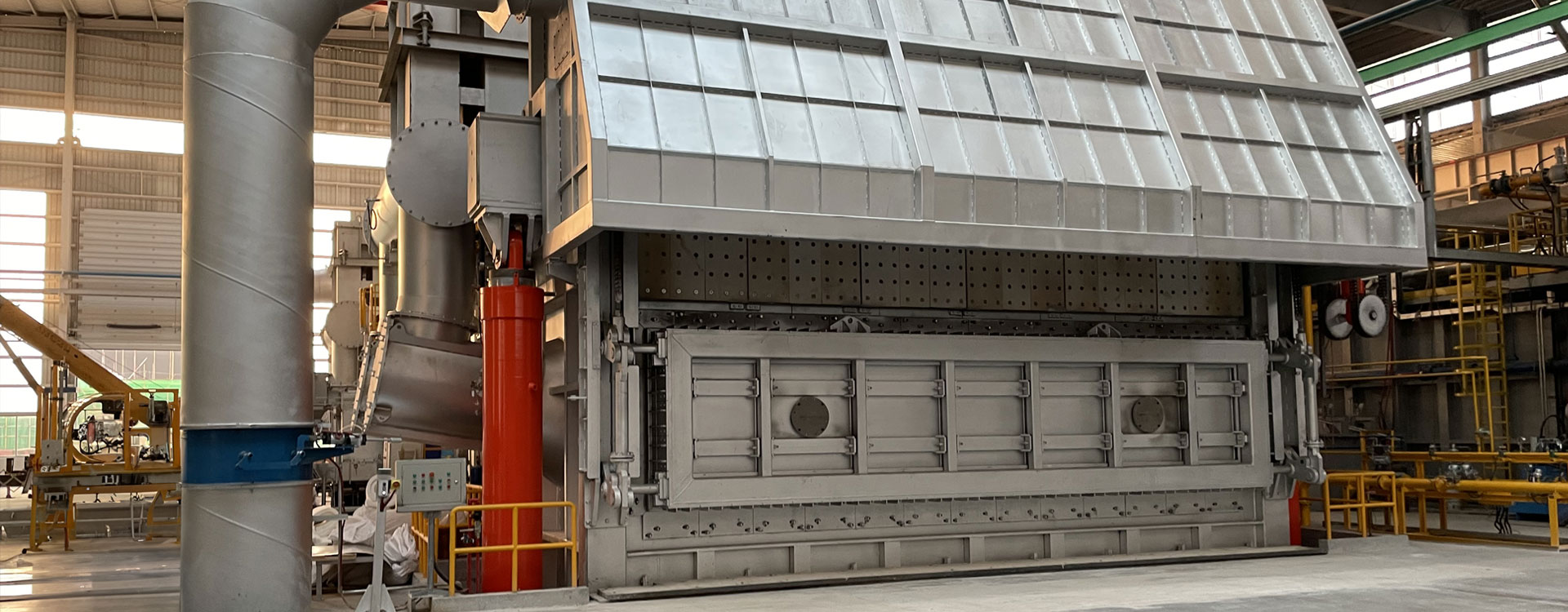

VAREGA ENVICOM®

Companies in the aluminum industry are finding it increasingly challenging to balance energy efficiency, environmental impact and operational safety. Gautschi has risen to meet this challenge by taking a long-term approach to technology, and can now present the VAREGAENVICOM® regenerative burner system: a system that has been specially developed for use in aluminum melting furnaces.

EQMS: Fabrication and manufacturing expertise at the highest level

With “enineering excellence and precision metalworking” as its guiding principle, EQMS has established itself as a reliable partner for challenging metalworking jobs since it was founded in August, 2022. EQMS has been operating since May, 2023, and since 2025 it has been based at a new, state-of-the-art workshop in Ramos Arizpe, Coahuila, Mexico. The company offers tailormade, individualized manufacturing solutions to international customers from many industrial sectors.

Manufacturing – keeping its finger on the pulse of the times

Key components for our heat treatment facilities are manufactured at the EBNER works in Leonding, Austria – everything from fan impellers and workbases to protypes. Our high-precision manufacturing is carried out by teams of specialists, who fulfill the highest quality criteria even as they meet the strictest deadlines.

EBNER sets new standards

Until now, conventional methods of measuring temperatures during a heat treatment process have been associated with extended interruptions in production and increased error frequencies. With the new and innovative temperature measurement system from EBNER, these problems belong to the past.

Innovation meets Industry

Metals processing industries are facing a steadilyrising demand for increased quality, efficiency and sustainability. This is especially true in the steel and copper base metals industries, where powerful descaling processes that make efficient use of resources are crucial for ensuring consistent product qualities and economical operation. To address this need, WRUtec employs a simple yet effective principle: pulsed water jets.