Furnace modernization.

EBNER.blog | Peter Andexlinger, EBNER

Furnace modernization.

EBNER is excited to partner with Logan Aluminum in their next adventure: maintenance and improvement of their EBNER furnaces.

Logan Aluminum has installed three EBNER pusher furnaces over the years, some of which have been running since the early 90s.

Logan Aluminum is an industry leader in developing innovative and effective ways to ensure strong reliability processes, creating clear reliability standards and objectives for their operations. This includes setting performance metrics, establishing benchmarks based on historical trend data and implementing systems to continuously monitor performance against these standards. The company follows a rigorous schedule for routine maintenance tasks, and its predictive maintenance program ensures that equipment is serviced regularly: potential issues are addressed before they become critical. As part of this emphasis on reliability, Logan partnered with EBNER to develop a long-term plan for keeping their furnaces healthy.

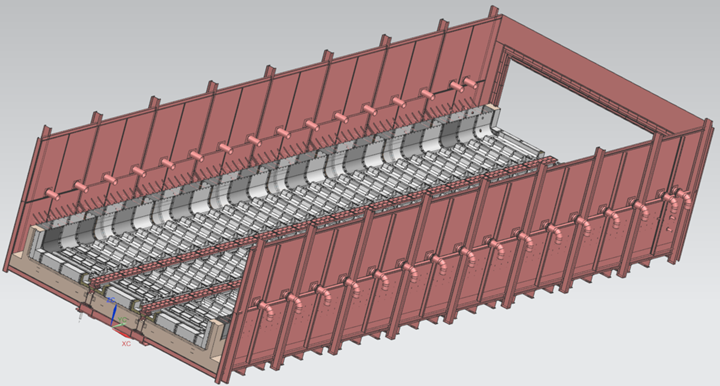

As with many other things, some TLC is required to ensure that equipment continues to operate efficiently and trouble-free in the future. For its furnaces, Logan started this process some time ago by rebuilding the internal elements of the sidewalls and roof. The existing inner casing, baffles, plenum chambers, and lining materials were removed, and the furnaces were upgraded to the latest design standards. It was then time to finish refurbishing the first furnace by rebuilding the rails, supports, and floor sections, a process that started a few years ago when Logan placed an order for a new set of supports and rails.

About a year later, the company ordered the remaining floor elements. These components are scheduled for installation next spring, and as one can imagine this will involve a major shutdown. Timing will be critical, as within a few short weeks the entire floor and support structure will be stripped down to the outer shell and rebuilt with new materials.

The rebuild project will require a large crew of welders, fitters and lining specialists, all working with EBNER’s installation supervisors and Logan’s maintenance crew. However, all those involved have developed and fine-tuned the logistics and planning for this type of upgrade over the years, and what may look like a daunting job at first has evolved into something that could almost be called routine.

As part of the preparations for the shutdown, Logan and EBNER have been working with the expected subcontractors to put a detailed schedule in place, including milestones for each phase of the project. Prior to the start of the outage, all materials will be on site, and staged to be ready for use, preventing delays during the installation phase. Another part of the pre-project preparation is the establishment of strong safety protocols, as Logan prides itself on having a strong safety culture across all facets of its business. The company takes extra steps during large projects both to ensure that all participating parties are aware of safety procedures and to ensure they are being followed, as well as to ensure that all equipment required to complete the job safely is on site.

Once the project is completed, the furnace will be brought back into operation for another long stint of productivity. Logan Aluminum and EBNER are working closely together to ensure that the pusher furnace modernization project is successfully completed, allowing the furnace to resume production with enhanced efficiency and reliability.