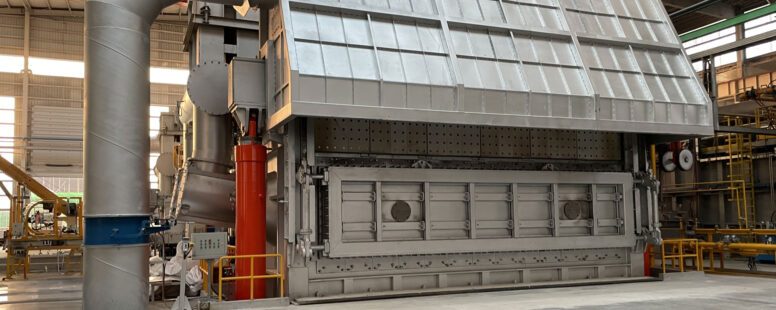

Efficient homogenization with state-of-the-art technology

Aluminum is one of the most versatile metals of our time: its light weight and strength make it indispensable in sectors like the automotive, aerospace and packaging industries. However, before a cast rolling ingot can enter the rolling mill, the microstructure within it must be perfectly prepared. This is where homogenizing heat treatment comes in.