Spiking Heat Treatment

EBNER Industrieofenbau | Manoj Kumar, VP Product Development

Spiking Heat Treatment

Spiking is a short and fast heat treatment process applied to solution annealed aluminum strip after quenching, creating specific mechanical properties in semi-finished or finished products.

THE USE OF SPIKING DURING THE MANUFACTURE OF AUTO BODY SHEET FROM AA6XXX ALUMINUM ALLOYS

Due to their strength, formability and low weight, aluminum alloys from the AA6xxx (Al-Mg-Si) series are often used for auto body parts. To support the ongoing effort to reduce vehicle weight, these alloys must be easy to form and increase in strength during the baking process for paint. Sheet was formerly supplied with a T4 temper, which simplified logistics but led to inconsistent characteristics and meant that the final strength after paint baking was inadequate.

In response, automobile manufacturers introduced reheating and two-stage heat treatments during the 1990s. These approaches were, however, unsuitable for high-speed production.

Development of the heat treatment process therefore continued, leading to the integration of reheat furnaces into continuous annealing lines. This integration allowed a pre-aging step to be carried out without slowing production. By the end of the 90s, this had become the standard for alloys like AA6016 and AA6111.

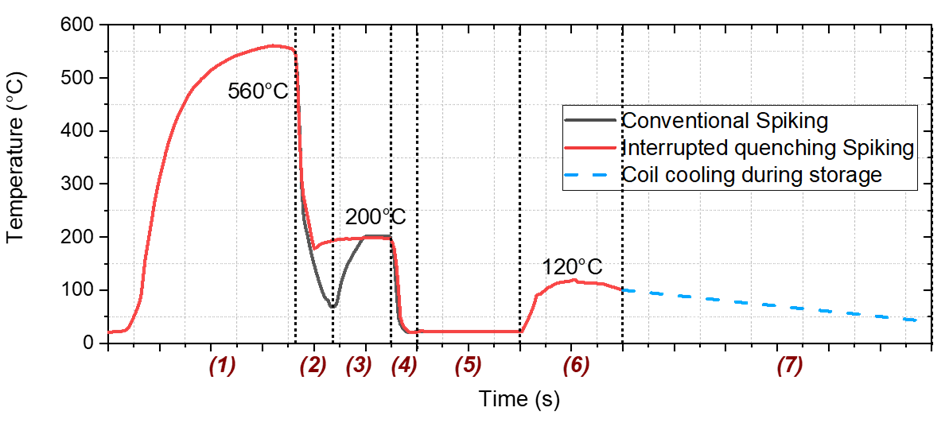

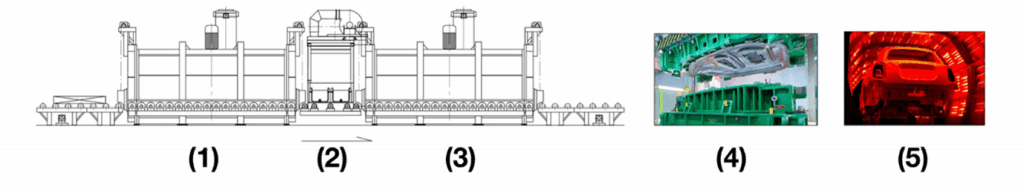

Figure 1 shows a schematic depiction of the heat treatment process for AA6016 sheet, including spiking heat treatment, at a CASH line. (1) solution annealing, (2) conventional or two-stage (interrupted) quenching, (3) spiking heat treatment, (4) cooling, (5) transfer time to reheat furnace, (6) reheating and (7) coil cooling during storage.

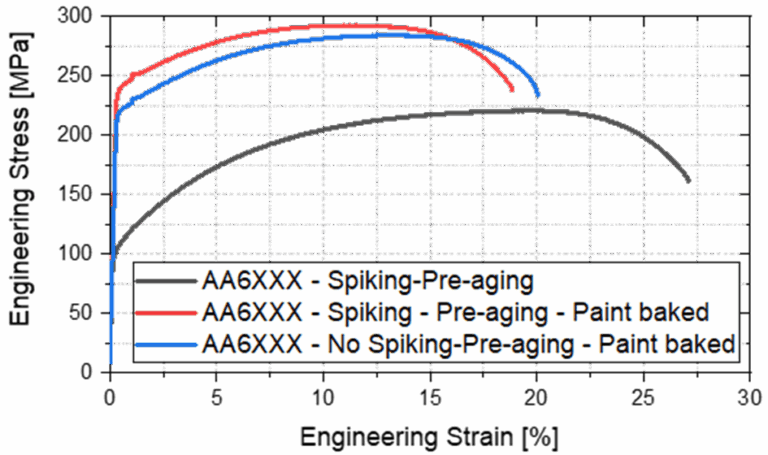

The next innovation was “spiking” – a short-duration heat treatment that followed quenching (fig. 1). During spiking, the strip is reheated to 100 – 300 °C for 5 – 60 seconds and then cooled down at a rate of 1 – 25 K/s. Spiking promotes the formation of clusters, even as it also improves behavior during hardening and the consistency of mechanical properties. Studies conducted by EBNER show that AA6016 sheet exhibits a 7 % increase in yield strength when spiking, pre-aging and baking are employed (fig. 2).

Figure 2. The effect of spiking on the behavior of AA6016 during baking.

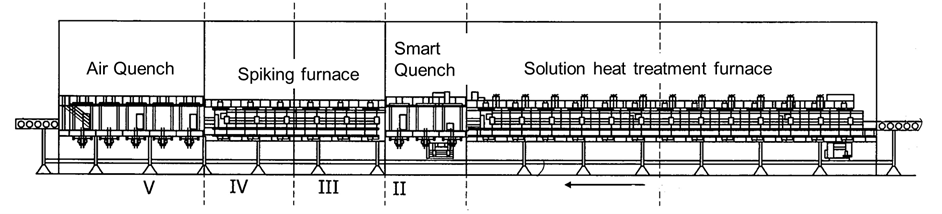

EBNER also developed and patented (WO2019141682A1) a system for integrating a spiking furnace into continuous (CASH) heat treatment lines, combining solution annealing, cooling in a SMARTQUENCH® and spiking in a single facility (fig. 3). This arrangement supports spiking heat treatment, as well as conventional or two-stage (interrupted) quenching (fig. 1). Both temperatures and times can be precisely controlled. The results include improved strength, reduced deformation and consistent mechanical properties from charge to charge.

Figure 3: CASH line with integrated spiking furnace.

The effectiveness of spiking depends on the composition of the alloy, stretching, temperature control, preaging and the conditions during baking. It has become one of the key techniques for improving the performance and reliability of AA6xxx aluminum during the manufacture of automobiles.

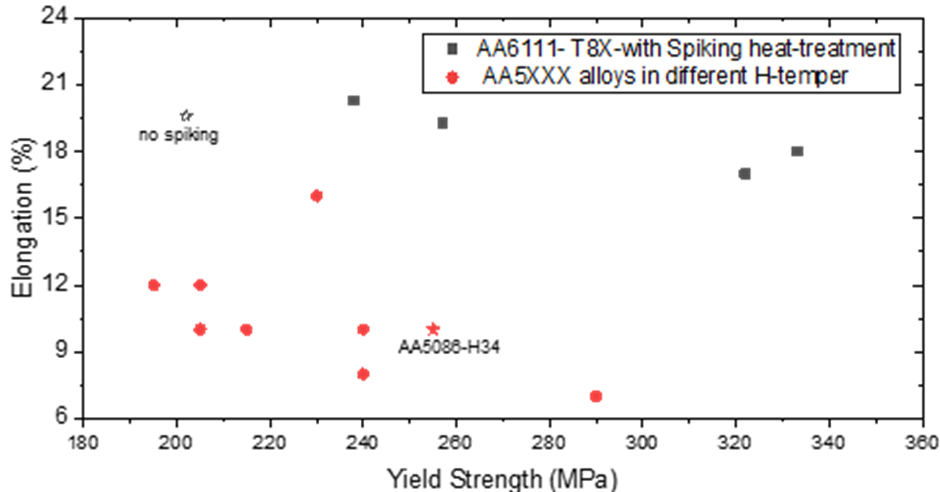

EBNER customers have confirmed the effectiveness of spiking heat treatment, with strengths increased up to 40 % after paint baking. Their experience shows that, with the proper selection of alloys and precise thermal control, a wide range of tensile properties can be achieved – without a need to subject the charge to an additional hardening process. Figure 4 shows that the yield point (YS) of AA6111 coils increases significantly during spiking heat treatment, meaning that the sheet specified for an auto body can potentially be downgauged. The yield point of AA6111 almost exactly corresponds to that of AA5xxx alloys with an H temper. However, the total elongation is much higher, meaning that AA6111 could replace 5086-H34 but offer far superior ductility.

Figure 4: Comparison of typical tensile properties of widely-used AA5xxx alloys (H temper) with AA6111 alloys (T8X temper) that have undergone spiking heat treatment.

THE USE OF SPIKING DURING THE PRESSING OF AUTO BODY SHEET FROM AA6XXX ALUMINUM ALLOYS

Abstracts of the patents issued to leading OEMs and research institutes list a variety of forming processes for AA6xxx and AA7xxx aluminum alloys. However, each process has its limitations – such as thinning, cracking or an inconsistent strength after hardening. In response, EBNER developed and patented (A2024-89041-WO) a new forming process with spiking (fig. 5). In this process, sheet is solution annealed before forming, quenched and then spiked. In comparison to W tempers and hot forming/die quenching, spiking significantly improves the material’s ability to be deep drawn – it is from 1.5 to 2 times better – and ensures that tensile properties are consistent. This increases process stability, reduces residual tension and improves both work hardening and paint bake strength, making it ideal for automotive components.

Figure 5: Manufacturing sequence for automotive components when forming with spiking (SPF). (1) solution heat treatment, (2) quenching, (3) spiking heat treatment, (4) pressing and (5) baking.

THE USE OF SPIKING DURING THE MANUFACTURE OF AIRCRAFT SKIN FROM AA2XXX ALUMINUM ALLOYS

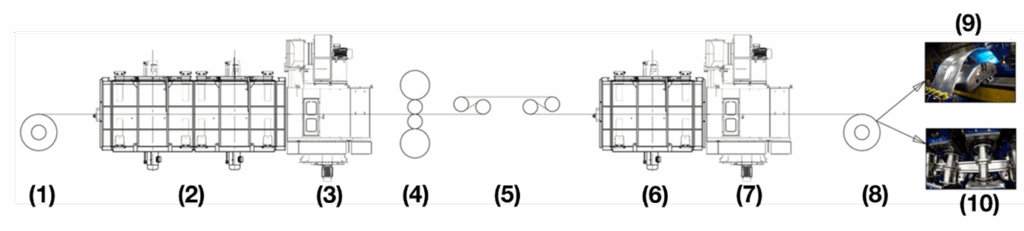

Aluminum alloys for aerospace applications must offer a balanced ratio between strength and ductility, while at the same time possessing excellent formability to allow the manufacture of complex fuselage shapes. Common forming processes employing T3, O or W tempers require more heat treatment steps and cold storage, leading to high production costs. EBNER’s investigation of the spiking heat treatment of AA2024 alloys showed that both formability and mechanical properties were significantly improved. Spiking for only a few minutes at 175 – 250 °C improved the ratio of Rm/Rp0.2 by over 10 % and also improved elongation, enabling the continuous production of fuselage skin with improved storage characteristics and reduced deformation. Based on these results, a new process path for AA2xxx alloys (fig. 6) was developed and patented (A2024/89041-AT) that combined spiking with continuous heat treatment in a CASH line (for sheet up to 6-8 mm) or with a roller-hearth furnace (for thicker sheet). This new approach offers aircraft manufacturers improved formability, stable mechanical properties and reduced operational complexity, making it an extremely promising solution for the efficient and high-quality production of aerospace components.

Figure 6: T3SP heat treatment of AA2024 in a CASH (Continuous Annealing & Solution Heat treatment) line. (1) pay-off reel, (2) solution annealing, (3) quenching, (4) skin pass rolling, (5) tension leveling, (6) spiking heat treatment, (7) cooling to reheat temperature, (8) take-up reel and (9) stretch forming or (10) roll forming.