A proven EBNER HIT(T)

/ Innovation & Technology, Success Stories

EBNER Industrieofenbau | Anton Oppermann, Product Manager

A proven EBNER HIT(T)

The first EBNER HITT bell annealer for high-temperature anneals of grain-oriented (GO) electrical steel strip processes the highest material qualities at Aperam South America Brazil.

Globally, increasing amounts of electricity are being used for industrial production, transport, electrification and in many other sectors. According to a forecast from the International Energy Agency, an annual increase in electricity consumption of almost four percent is expected by 2027. In addition, global electricity demand will continue to increase at least until 2040.

This increasing demand requires efficient solutions for power distribution networks, networks in which transformers play a central role. That is, transformers are essential components of any power distribution network, as they are needed to convert current into a suitable form before it can be transported or used. The cores of transformers used for this conversion consist of efficient grain-oriented electrical steel strip, which is also known under a variety of names such as silicon steel and transformer steel.

To ensure the quality of this special material, state-ofthe-art heat treatment processes are needed – processes such as those carried out in the EBNER HITT® (High Temperature & Tight) facility installed at Aperam South America’s Brazilian works. This facility was specially developed for high-temperature anneals of grainoriented electrical steel strip, and provides optimum material quality.

The rising customer demand for increased coil weights and improved temperature uniformity, paired with a need to keep the operating costs for high-temperature anneals of grain-oriented electrical strip as low as possible, are what led Aperam to choose EBNER as the supplier of their new high-temperature bell annealer facility. In contrast to other existing facility designs (multi-stack furnaces sealed with sand), an EBNER HITT® bell annealer provides a complete, gas-tight separation of the workload space and the combustion chamber.

This separation allows a precisely controlled atmosphere to be achieved, significantly reducing hydrogen consumption. A special patented coil support enables the coils in the workload space to be heated uniformly and efficiently, leading to a significant reduction in scrap.

Paired with a cooling bell, this system ensures the shortest possible processing times. It provides the highest productivity, paired with the best possible quality and high throughput. The safety concept for processing in hydrogen has been adopted from HICON/H2® bell annealers, and either an electric or a gas-fired heating system can be installed.

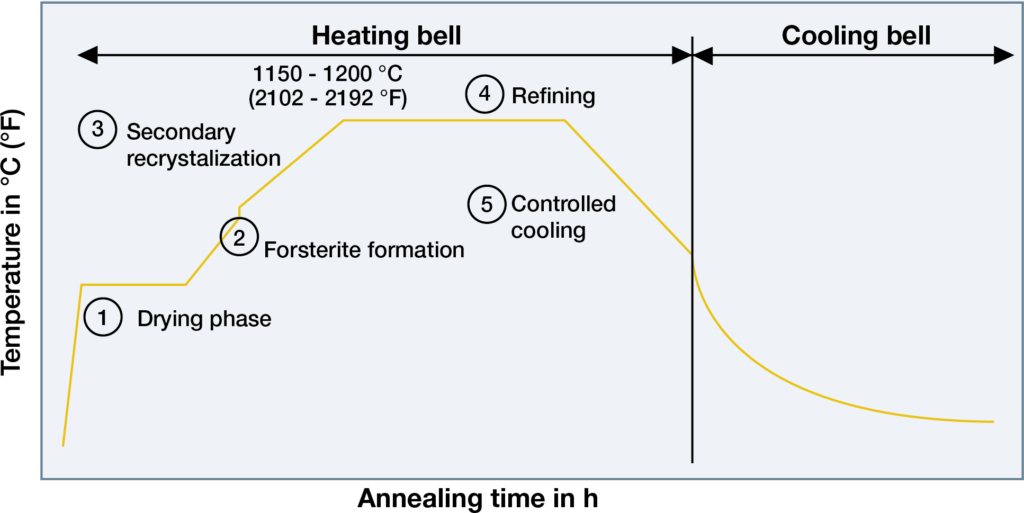

The processing steps (1 – 5) carried out by the bell annealer are schematically depicted in the figure shown below. High-temperature anneals use secondary recrystallization to form grains with the magnetically advantageous Goss texture (3). The high processing temperatures (above 1150 °C) and straight hydrogen atmospheres also remove sulfur and nitrogen from the material (4). At the start of heat treatment, a drying phase (1) is used to dry the MgO coating applied during an upstream process. This inhibits the formation of stickers in the wraps at high processing temperatures by forming a Forsterite layer (2).

The following advantages contributed to Aperam’s decision to choose an EBNER HITT® bell annealer over a multi-stack sand-sealed design:

- Lower utility consumption (H2, N2), due to the gas-tight encapsulated workload space

- Lower energy consumption (reduced fuel gas consumption)

- Homogeneous temperature distribution within a coil, due to the patented coil supports and symmetrical heating; this ensures

- homogenous magnetic properties

- reduced scrap due to reduced amount of strip

edge damage - shorter annealing cycles (heating-up)

- long inner cover service life

- Cooling in 100 % H2 atmosphere and use of a cooling bell provide:

- significantly increased productivity

- improved surface finish

- prevention of further nitriding

TECHNICAL DATA OF REFERENCE FACILITY:

Diameter: 2000 mm

Charging height: 3000 mm

Maximum

net charge weight: 44 t (2 x 22 t)

Heating system: Gasbefeuert

Scope: 1 workbase, 1 heating bell, 1 cooling bell