EBNER GROUP

News and Reports

As a globally active group of companies, the EBNER GROUP comprises numerous specialized companies in the field of heat treatment and high-performance materials, including EBNER Industrieofenbau, EBNER Furnaces Taicang, EBNER Furnaces, EED, ETS, Gautschi, GNA, HPI, C-R-C, TPS, Hazelett, FAMETEC, EEMCO and SiCreate. Here you will find all official press releases, the latest company news and important industry updates. We keep you up to date on groundbreaking developments, technological innovations and international projects.

MORE INFORMATON

EBNER GROUP Marketing & Communication

[email protected]

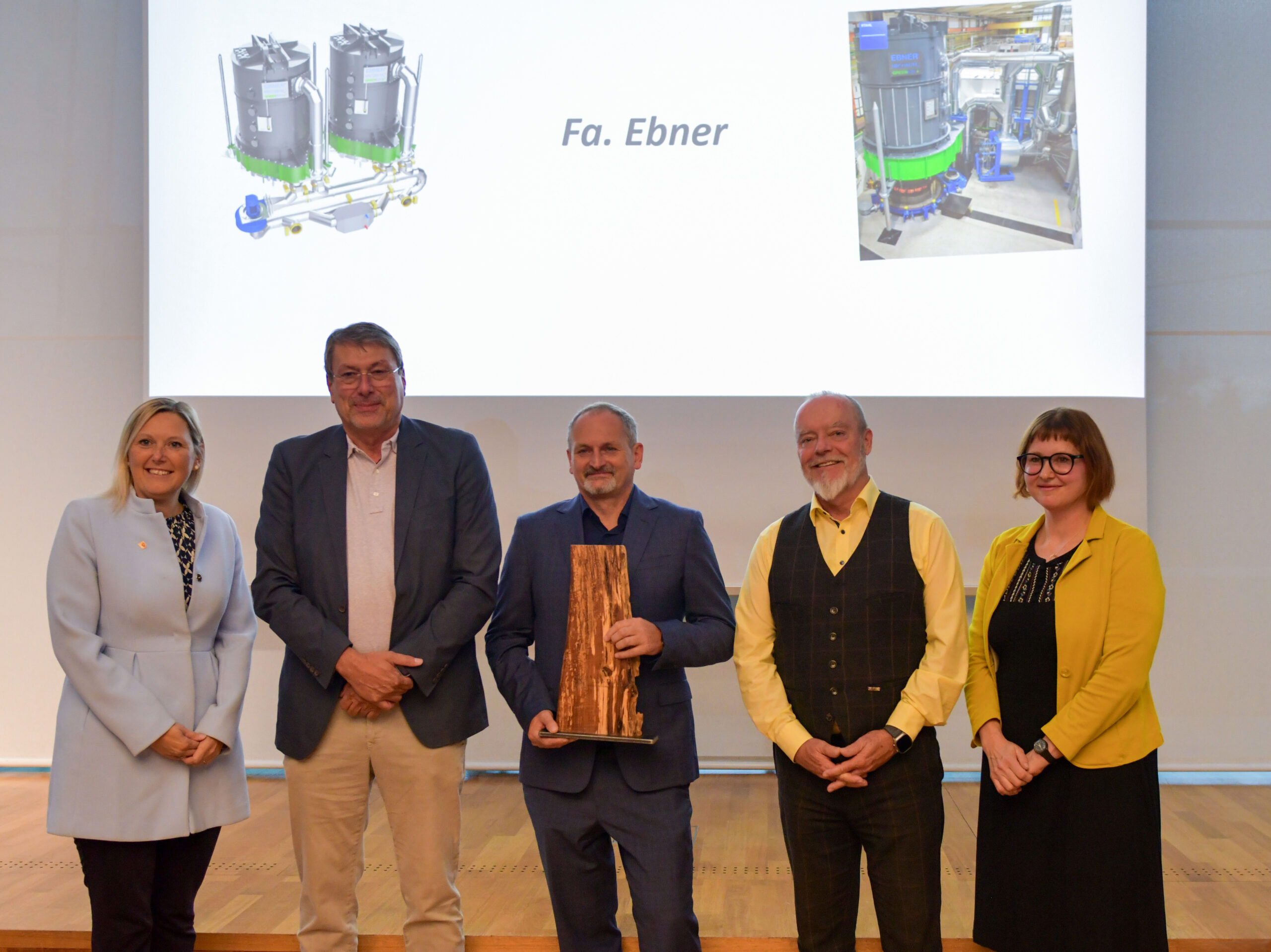

EBNER wins the “Leondine” climate protection award

The city of Leonding has awarded EBNER Industrieofenbau the “Leondine” environmental and climate protection award. This honor recognizes our contribution to the development of sustainable technologies that make a significant contribution to climate and environmental protection.

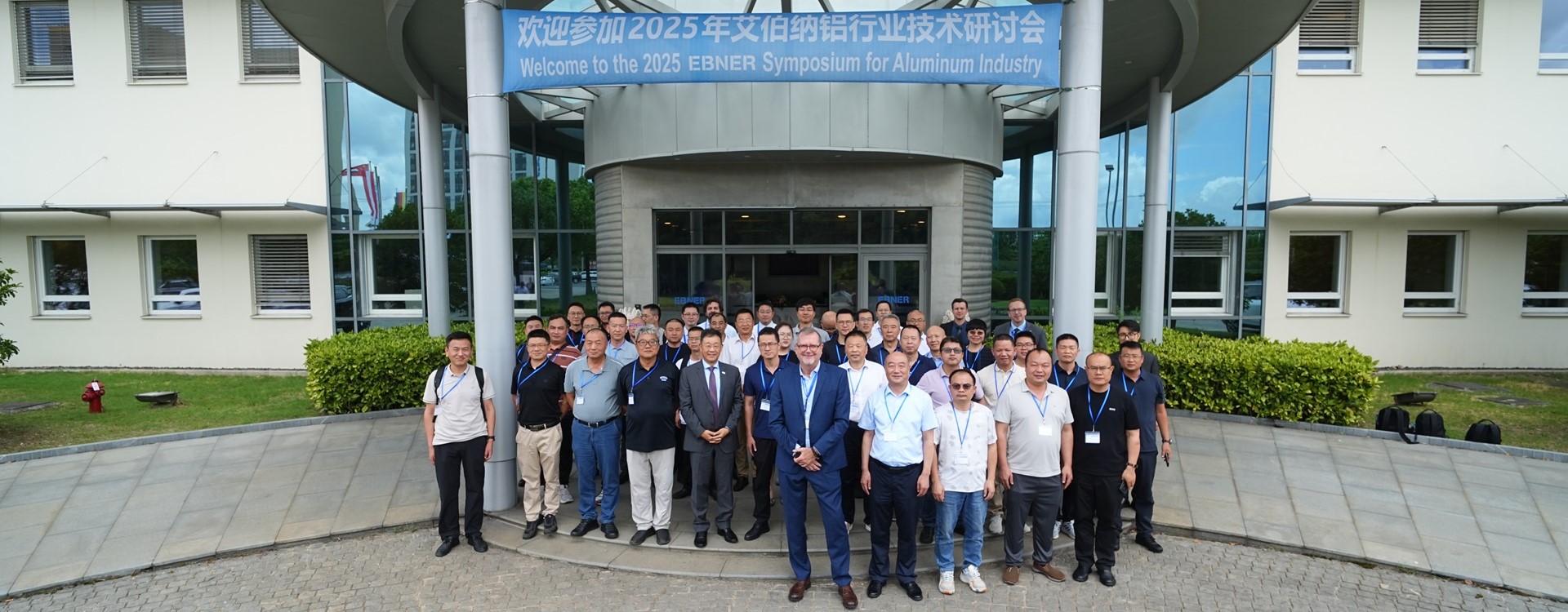

EBNER Symposium for Aluminum Industry

From July 7 to 8, EBNER China hosted a high-profile technology symposium for the aluminum industry. Industry experts from Southeast Asian agencies, customers and Chinese companies came together to discuss technological trends and solutions for aluminum processing.

“A nose for science” nook for Kindergarten Alkoven

Following the successful implementation of three “A Nose for Science” nooks in Leonding and Wilhering, the EBNER GROUP continues its commitment to early childhood education and the promotion of scientific discovery. The fourth nook has now opened at the municipal kindergarten in Alkoven.

New HAZELETT Management

HAZELETT Strip-Casting Corporation announces the retirement of long-time President, David Hazelett, effective December 31, 2024. After decades of dedicated leadership and contribution to the company’s success, David will transition his management responsibilities to the offices of Co-Managing Directors, Dave Diederich and Jim St. Germain.

GNA alutech inc. is now fully owned by EBNER GROUP

EBNER GROUP, a global leader for melting, casting and heat treatment solutions for the aluminum industry with the companies EBNER, ETS, EED, Gautschi, TPS, Hazelett, HPI and GNA, has increased their stake in GNA alutech inc. to 100%.

Kindergarten Hainzenbachstraße gets a new EBNER “A Nose for Science” nook.

At the Hainzenbachstraße kindergarten in Leonding, all children can now playfully discover and learn about the fascinating world of technology and science in the “A Nose for Science” nook sponsored by the EBNER GROUP.

New GNA Management

GNA alutech inc. celebrates 40 years of excellence in the aluminum industry as a supplier of equipment and technology. CEO Ted Phenix hands over the reins to longtime employees Chantal Coupal and Kaleb Wright.