EBNER Software Excellence

EBNER Indien| Sureshram Varadarajan Maier, Country Manager

EBNER software excellence

How the EBNER GROUP’s global software hub in India is driving digital transformation in industrial furnace technology.

In the world of industrial furnaces, a new revolution is underway. While hardware remains essential, the true power of a furnace now lies in its software. Furnaces today are no longer standalone products — they are intelligent, connected systems that rely on software for performance, efficiency, and long-term reliability.

At the EBNER GROUP, we have made a strategic decision to put our customers at the forefront of this digital transformation. We have established our Mumbai, India

office as the global hub for industrial software development for all EBNER GROUP companies.

This move is backboned by our aim of building smarter and more efficient furnaces, giving customers a competitive edge by making use of India’s global software technology powerhouse.

A GLOBAL COLLABORATION FOR EXCELLENCE

India is a recognized leader in software technology, but its expertise goes deeper. For decades, Indian engineers have been building the specialized industrial software that powers factories, robotics, and large-scale manufacturing equipment. Having established its Mumbai subsidiary in India in 2009 as a service center, EBNER has strategically expanded its capabilities, leveraging the unique combination of deep engineering knowledge and cutting-edge software skills within the Indian workforce. The ability of the Indian team to scale with EBNER‘s growth makes the subsidiary an ideal location to serve as the global software hub for all EBNER GROUP companies. This allows the delivery of solutions that are perfectly tailored to customer needs. With more than 5 million IT professionals, India combines scale with specialization, making it an ideal home for the EBNER GROUP software hub.

The Mumbai software hub is not an isolated outpost but part of a globally integrated development team. Our teams in India and Austria work hand-in-hand, each contributing their strengths. The Indian team is deeply integrated into the development of advanced software systems, bringing their technical expertise and agility to the forefront. At the same time, the Austrian teams contribute decades of furnace-building experience, ensuring software innovations align with mechanical engineering excellence and real-world customer needs. This collaborative model is built on shared ownership and mutual respect. Daily virtual meetings, joint design sessions, and exchange programs ensure ideas flow freely across borders.

OUR CUSTOMERS’ BENEFITS

The new software hub in India will become the backbone of our group’s digital transformation, building furnaces that are smarter, more reliable and easier to maintain. This includes:

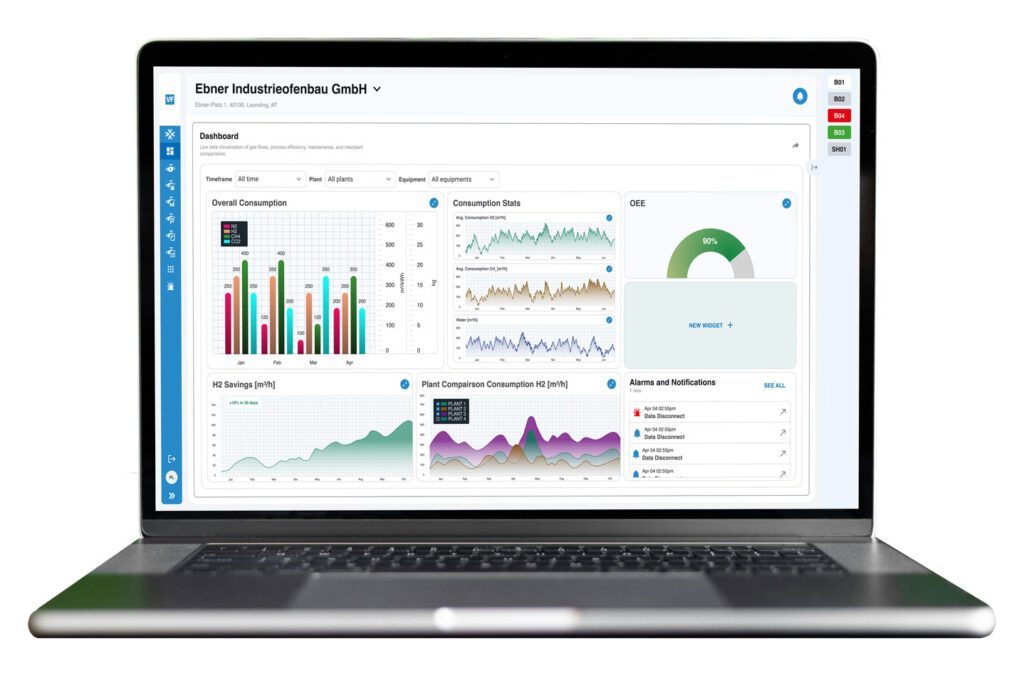

- Control and automation systems: Software for PLCs, HMIs and furnace controllers.

- Predictive maintenance: Data analytics that help customers avoid downtime.

- Digital twins: Virtual models of furnaces for testing, training, and optimization.

- Industrial IoT platforms: Connectivity between furnaces, sensors, and production systems.

- Customer apps & interfaces: Tools that give operators and managers real-time insights.

Representative image, without actual data

The Indian subsidiary is already home to talented engineers working in software engineering, commissioning & service, electrical & automation and mechanical engineering. Their work will now be scaled up and integrated into all possible EBNER GROUP projects.

The future of furnace building is connected, intelligent, and sustainable. Our software hub in India positions us at the heart of this transformation:

- Connected furnaces that share real-time data with operators worldwide.

- AI-driven quality control that ensures precision and reliability.

- Green digital solutions that optimize energy use and reduce waste.

India’s software excellence, combined with the EBNER GROUP’s engineering expertise, creates a powerful combination: furnaces that are not just built, but engineered for the future green environment and to achieve a new level of operational excellence.