STC Heat Treatment Furnaces

/ Innovation & Technology, Success Stories

EBNER.blog | Liu Ning, EED

STC Heat Treatment Furnaces

Protective atmosphere roller type short cycle annealing furnaces.

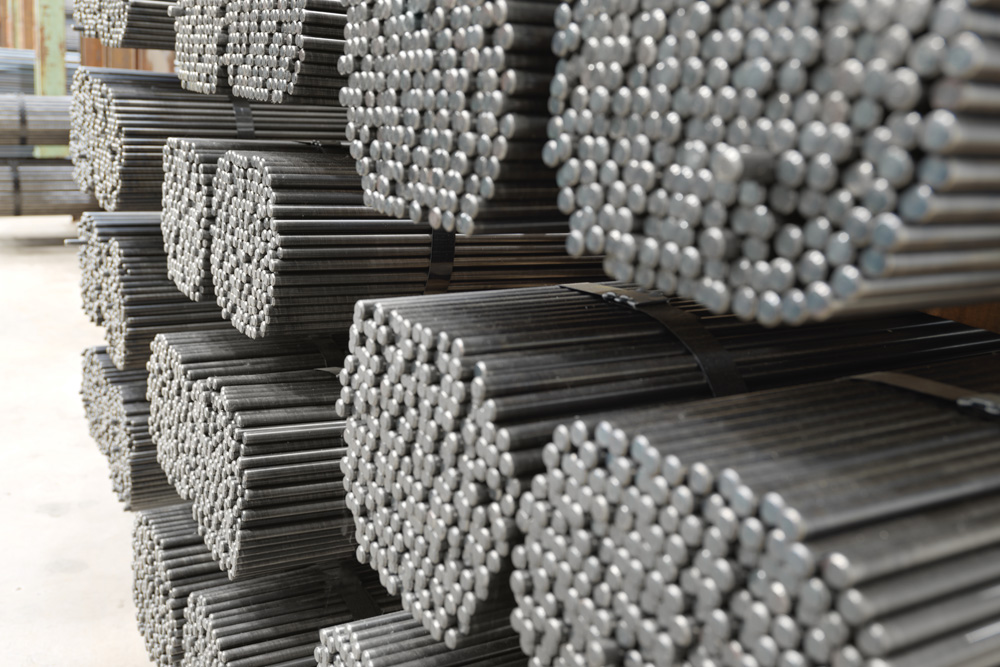

A protective atmosphere roller type short cycle annealing furnace, generally referred to as an STC furnace, is primarily used to bright anneal products such as bar, wire, and copper pipe, improving the uniformity of their structures and enhancing their ability to undergo mechanical processing.

High quality products such as standard high-grade, high-strength parts, cold formed automotive parts, and bearing steels often require steel wire to be annealed during the refining process (before production) to reduce tool wear and improve product yields. Heat treatment also facilitates cold heading forming, reduces hardness, improves the structure and ensures good mechanical properties are obtained.

An STC furnace is an essential piece of equipment for completing this process.

Jiangsu Tiangong Tools Co., Ltd. is a supplier of comprehensive solutions for the cutting tool manufacturing industry, primarily focused on the production and sale of carbide steel and high-speed steel cutting tools.

In February 2022, Jiangsu Tiangong Tools Co., Ltd. signed a contract with EED Company, a member of EBNER GROUP, for the purchase of gas-fired roller type short cycle annealing furnaces using RX gas as a shielding gas. These furnaces would improve the mechanical properties of Jiangsu Tiangong Tools’ alloy and highspeed tool steels, enhancing the market competitiveness of its cutting tool product line.

A gas-fired RX atmosphere roller type short cycle annealing furnace is a typical STC furnace. Such a STC furnace prepares an endothermic reaction atmosphere by cracking natural gas for use as a shielding gas during heat treatment in the furnace, which can effectively limit the occurrence of additional decarbonization.

Cracking is carried out using an endothermic gas generator, a device that mixes natural gas with a corresponding amount of air. When subjected to the action of high temperature and catalyst, this mixture undergoes incomplete combustion to produce a special atmosphere commonly referred to as RX gas.

The process for preparing an endothermic atmosphere using natural gas follows the formula CH4+2.38 air -> CO+2H2+1.88N2, and when natural gas is used as the cracking gas the final composition of the RX gas includes about 20 % CO and about 40 % H2.

The atmosphere inside the STC furnace is a mixture of CO, N2, H2, and CO2. To control the atmosphere in the furnace and maintain the pressure inside it, the workload space inside the furnace must always be isolated from the air outside to prevent both the admixture and leakage of air. To maintain a particular carbon potential in the furnace, as well as to control the stability of atmosphere composition, it is also necessary to automatically control the atmosphere in the furnace in response to different processes. A variety of monitoring instruments and devices such as CO and CO2 analyzers, O2 analyzers, etc., are therefore essential. These regularly or continuously measure the atmosphere in the furnace to adjust the gas supply.

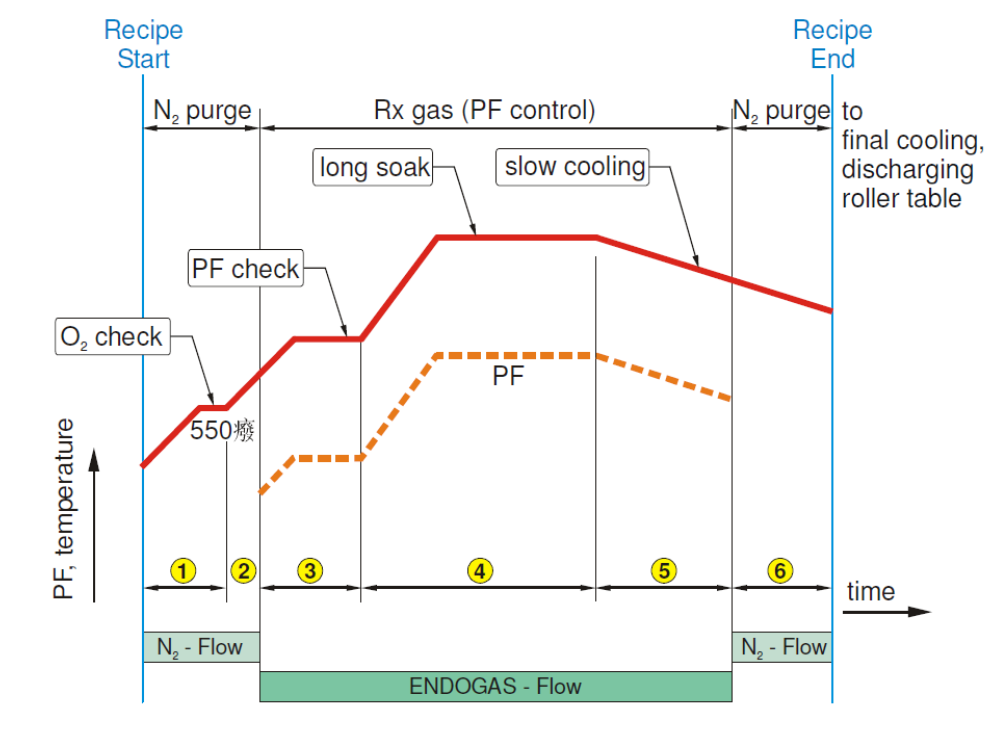

The material is initially purged with nitrogen gas while heating up. When the furnace temperature reaches 550 °C, the oxygen content in the furnace is measured. If less than 1 %, the temperature continues to increase. Once the temperature exceeds 630 °C, RX gas is fed in and the material undergoes the annealing process in process atmosphere.

Once the material temperature is below 650 °C, the entry of RX gas is stopped and nitrogen is forced in until the CO content is below 4 %. The furnace door at the outlet of the heating chamber can then be opened and the heating process is finished.

Using a given material as an example, the material is heated up to 20 – 30 °C above its Ac1 temperature (which is 770 °C in this example) and held there for a certain period of time. Controlled cooling is then carried out: the material is slowly cooled down to 670 °C before being discharged from the furnace and entering the cooling chamber for cooling.

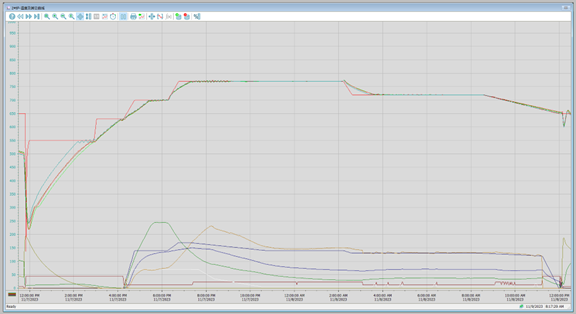

The curves in the upper part of the image are the trend curves for the setpoint and current value of the temperature, while the curves in the lower part of the image are the trend curves for the setpoint and current value of the atmosphere.

The contract with Jiangsu Tiangong Tools will be executed in two phases, with two annealing furnaces installed in each phase. Currently, delivery and commissioning of the first phase have been completed and we are looking forward to the start of the next phase of the contract.