Digital Product Management.

/ Digitalization, Innovation & Technology

EBNER.blog | Peter Gosch, EBNER, Austria

Digital Product Management.

Model Predictive Control - MPC

EBNER’s digitalization strategy incorporates four thematic areas: digital models, digital facility operation, virtual commissioning and digital customer service. As a part of this approach, EBNER has placed a strong focus on the concept of TCO (Total Cost of Ownership). This raises the question of how EBNER facilities can be operated to provide even further optimization of processes and costs.

Experts in each individual field have been advancing digitalization and our four areas of focus for some time, so in 2021 it was finally time to gather these experts together in a high-powered team and allow them to continue moving forward as Digital Product Management.

In this article, we would like to take a closer look at the topic of digital models – in particular, at the advantages of Model Predictive Control (MPC).

MPC has increasingly established itself as an important component of modern automation solutions. It has a great deal of potential in the field of industrial furnaces, as well.

EBNER is working intensively on the development of mathematical models for wide variety of furnace types. Alongside classical functions like the calculation of charge or strip temperatures and the calculation of optimized recipes, Model Predictive Control (MPC) offers a wide range of useful, future-oriented possibilities.

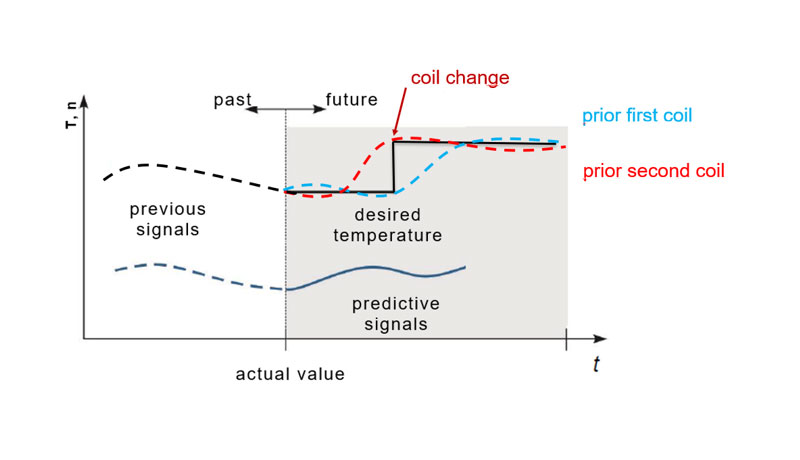

Based on a mathematical model of the furnace, Model Predictive Control (MPC) can calculate future conditions and so depict the future course of dynamic processes in the furnace.

This will allow a wide variety of promising features to be implemented in the future, which we will briefly introduce below.

OPTIMIZATION OF TRANSITION PHASES

A classic example is the optimization of strip transition phases in continuous heat treatment facilities. Predictive adjustment of the furnace setpoints can significantly reduce the amount of scrap strip.

The minimum possible length of any required transi-tion strips can be precisely calculated, increasing facility throughput. The exact calculation and recording of strip temperature, even during the transition phase, also allows the quality of the strip ends to be assessed.

OPTIMIZED FACILITY OPERATION BASED ON VARYING TARGET PARAMETERS

Model Predictive Control (MPC) also opens new possibilities for ways in which a facility may be operated. Along-side operational strategies that emphasize the maximization of throughput, minimize the stress placed on critical facility components or minimize scrap, strategies that optimize energy use are becoming increasingly important.

ROUTINES TO HANDLE MALFUNCTIONS

Malfunctions frequently require the recalculation of various furnace setpoints, such as the setpoint temperature or strip speed. To enable production to continue, Model Predictive Control (MPC) can calculate corrected annealing programs for every subsequent charge – all the way up until the malfunction is remedied.

SELF-OPTIMIZATION AND PREDICTIVE MAINTENANCE

The continuous evaluation of data collected in the past allow the system to optimize itself. The plausibility of the values collected by the array of sensors in the furnace is continuously calculated, allowing the early detection of measurement errors and defects that may develop in a variety of facility components.

THE NEW POSSIBILITIES OF VISUALIZATION

High-performance models allow the depiction and effective analysis of historical data and values. Data that is more current, along with the prognostic values calculated by Model Predictive Control (MPC), allow production to be optimally planned.

Optimization of transition phase