SICREATE – the expert in silicon carbide powders.

EBNER.blog | David Callejo, Robert Peter Ebner, SICREATE

SICREATE - the expert in silicon carbide powders.

The new generation of high-quality SiC powders for the semiconductor industry.

SICREATE, founded in 2021, specializes in the development and production of silicon carbide powder. This powder is used as a raw material in various applications in the semiconductor industry.

Our dedicated team of researchers and technicians works out of the headquarters of the EBNER GROUP in Leonding, Austria, as well as our R&D Center in Lomagna (LC), Italy.

As part of the EBNER GROUP, the company supplies EEMCO (also a member of the EBNER GROUP) with material and thus benefits from the presence of a close partner for the continuous development and improvement of SiC powder.

As an economically-competitive European manufacturer, SICREATE contributes to the sustainability goals of the EBNER GROUP with a resource-conserving production process and thus an environmentally-friendly product.

SICREATE Products

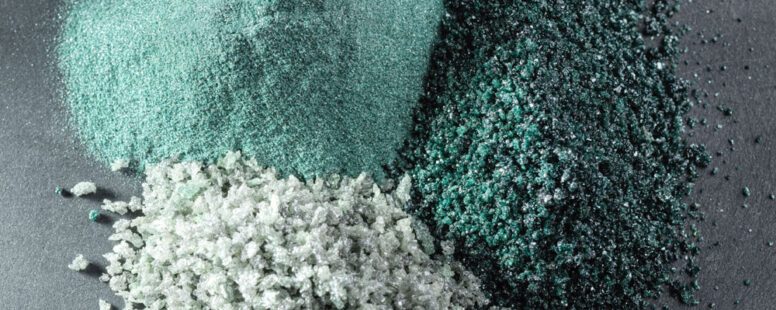

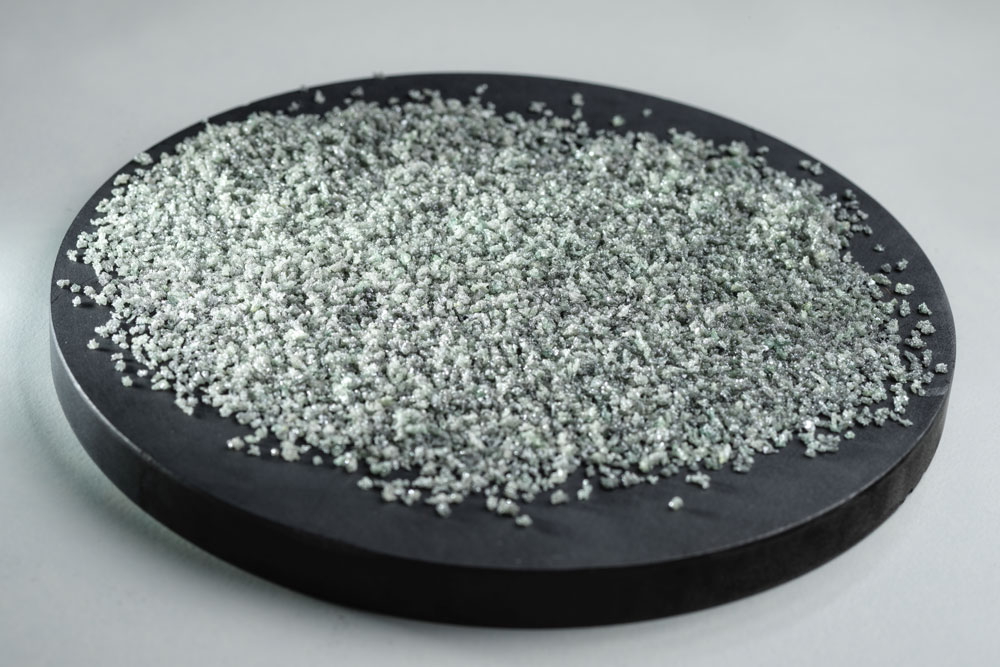

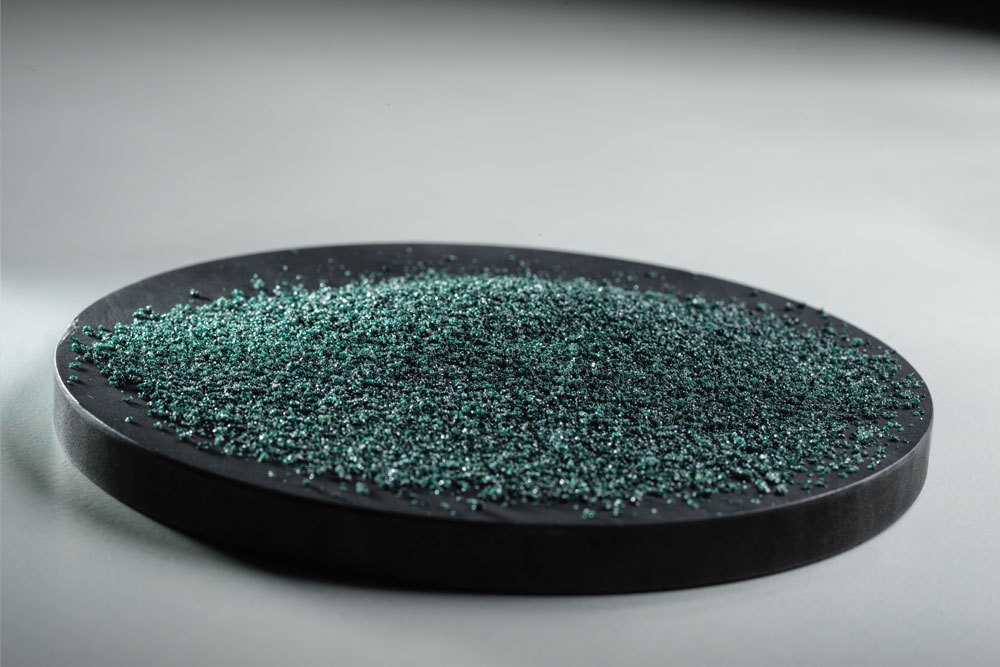

SICREATE is able to produce 2 types of SiC powder at a 6N purity level and with a grain size of 0.1 mm – 2 mm, in the colors green and light gray. The green powder is conductive (N < 30 ppm), while the light gray is semi-insulating (N < 1 ppm). SICREATE’s high quality standards are reflected in the fact that no mechanical or chemical post-treatment of the powder is performed, with the purity level and granulometry achieved during a single production cycle. Compared to other silicon carbide powders available on the market, SICREATE‘s powder features versatile granulometry, low stable nitrogen content, the lowest possible amount of metallic impurities and no chemical impurities, and a low CO2 footprint.

In the spirit of promoting circular economy, SICREATE offers recycling of customer raw material to produce new, high-purity silicon carbide powder that can be reintroduced into the semiconductor supply chain.

SICREATE technology

SICREATE produces its material using an ultra-high vacuum silicon carbide sintering process. This process is characterized by a high-temperature solid state flash reaction in an ultra-high vacuum atmosphere. Also of note is that this is a single step sintering process without any post-treatment, either mechanical or chemical.

SICREATE markets

SiC powder is used in a variety of applications in a number of markets. They include, for example, technical ceramics, defense and security, automotive, electronics and aerospace.

Technical ceramics

Silicon carbide is an attractive material for a variety of technical ceramic applications due to its specific properties such as chemical inertness at all temperatures, thermal shock resistance, abrasion resistance and sinterability. The main applications of SiC in the technical ceramics industry are the manufacture of kiln furniture, fluid handling equipment, bearings and wear parts, as well as ballistic protection and diesel particulate filters.

Electronics

The specific properties of silicon carbide make it an attractive material for a wide range of electronic applications. The main application of SiC powder in the electronics industry is the manufacture of kiln furniture and process components for the semiconductor industry, as well as for electrical field grading and surge protection.

Aerospace

In the aerospace industry silicon carbide is used to create both mirrors and structures, as the properties of silicon carbide make it a desirable choice for these end products. Silicon carbide is lightweight and rigid, making it particularly suitable for use in aircraft and space vehicles. It is also resistant to thermal shock, preventing mechanical fatigue and damage from extreme temperature changes. Over and above these advantages, silicon carbide is resistant to moisture absorption and the deterioration caused the radiation encountered in space. These properties make it a strong contender in the aerospace industry, well able to compete with materials such as beryllium for use in mirrors.

Click here to learn more about SICREATE!