EEMCO: your Europeansource forsilicon carbide.

/ Innovation & Technology, Sustainability

EBNER.blog | Stefan Defregger, EEMCO

EEMCO : your European source for silicon carbide.

The next generation of energy-saving, high-tech materials for the semiconductor industry.

EEMCO was founded at the end of 2020, and is a part of the EBNER GROUP’s ADVANCED MATERIALS business unit.

Over the course of 12 years of research and development work dedicated to the design and manufacture of crystal growth equipment, our company successfully developed dedicated furnace facilities designed to grow SiC single crystals with the 4H process. In the meantime, we have taken the next steps toward the manufacture of 8″ 4H SiC single crystals. These crystals are used in high power applications, particularly those found in the automotive, industrial and renewable energy sectors.

EEMCO currently operates 15 research furnaces, in which SiC single crystals are grown using a PVT (Physical Vapor Transport) process. In such a process, a single crystal is grown in an SiC vapor phase. EEMCO’s goal is to be the first independent company in Europe to produce these types of SiC crystals and be a manufacturing source for these strategic, high-tech products, offering a high-quality alternative to suppliers in the USA or China. As a sustainable product that saves energy, SiC is making a significant contribution to the reduction of CO2 in a wide variety of market sectors and consumer products.

EEMCO products

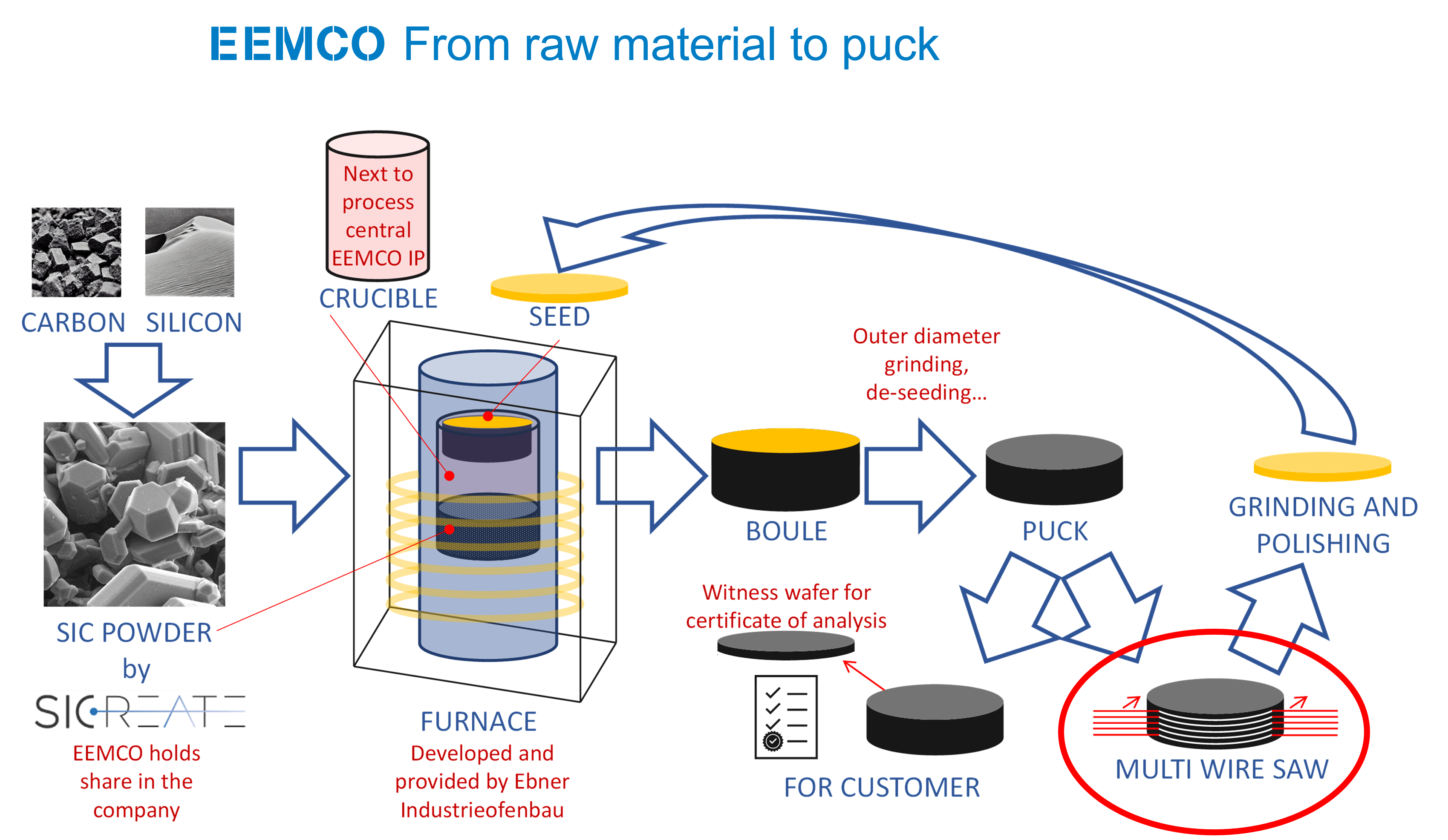

EEMCO specializes in the manufacture of high-quality 6” and 8” pucks, using proprietary furnaces and process technology.

Compared to 6″ wafers, 8″ wafers offer a significant increase in capacity: they provide almost twice the usable area for manufacturing integrated circuits, delivering from 1.8 to 1.9 times as many chips. Over and above this, EEMCO fulfills the requirements for thin wafering technologies and so reduces the wafer thickness by at least a factor of three. Among the essential criteria for the economical use of SiC single crystals is the lowest possible density of defects in a single crystal. However, at the same time wafers must be as large as possible (a 6″ wafer is now standard, with 8″ wafers soon to be introduced). This requires an absolute mastery of the complex technology for crystal growth, as provided by EEMCO.

EEMCO technology

EEMCO technology is centered around the development of a process model for 6″ and 8″ pucks. We use only SiC powders and granulates that we have developed ourselves.

EEMCO markets and applications

Automotive industry

The demand for electric drives in motor vehicles has been increasing rapidly, and with a market share of over 60 % they are by far the most significant factor in the market for high power electronic devices. In turn, this has created an increasing demand for highly-efficient

semiconductors for use in electric/hybrid vehicles (EV/HEV). The higher efficiency and power density provided by SiC lead to increased ranges, better-dimensioned systems and faster charging times. Typical applications include highly-efficient inverters, on-board charging electronics, boosters and DC/DC converters.

High power electronics

Auxiliary power supplies are needed in a wide variety of industrial applications. Among other uses, these applications include drive motors, inverters and industrial manufacturing equipment (including robotics). With its unique properties, SiC has greatly contributed to improvements in the energy efficiency, reliability and performance of these systems. Typical devices using SiC-based technology range from Schottky diodes (also called Schottky barrier diodes, or SBDs) to junction-gate FETs (or JFETs) and MOSFETs. In fact, SiC SBDs are widely used in IGBT power modules and power factor correction (PFC) circuits. In these applications, SiC does not just increase efficiency – it also reduces cooling requirements. It also simplifies device design, in that it reduces the number of passive components and enables simpler designs – without sacrificing performance. These characteristics are also very useful in the IT industry, particularly in data centers.

Renewable energy

Solar power, wind power and renewable energy storage are market segments that display remarkable growth. While renewable energy has been a favored application for SiC products for many years, ongoing climate and energy crises have increased the demand for alternative energy sources even more. Common applications again involve high-efficiency electronic power devices like inverters and boosters (power converters), as well as essential components for power conversion and energy storage systems. Typical charging losses for such devices range between 6 and 9 %, values that can be dramatically reduced by applying SiC technology. SiC-based device technology also reduces the need for complex circuit designs, requiring fewer overall components and minimizing charging losses.

Click here to learn more about EEMCO.