Zero-emission heat treatment

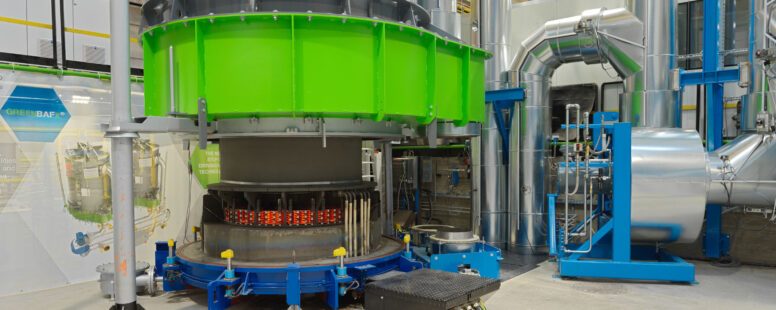

Decarbonizing the steel industry is essential – especially energy-intensive processes like heat treatment. In this interview, Sascha Eppensteiner explains how emission-free technologies such as electric direct heating and smart heat recovery systems, exemplified by the GREENBAFx®, contribute to climate-neutral production while remaining economically viable.