ECOBURN FL in focus

/ Innovation & Technology, Sustainability

EBNER Industrieofenbau | Peter Seemann, Senior Principal Expert | Michael Koller, Senior Product and Business Developer Customer Services

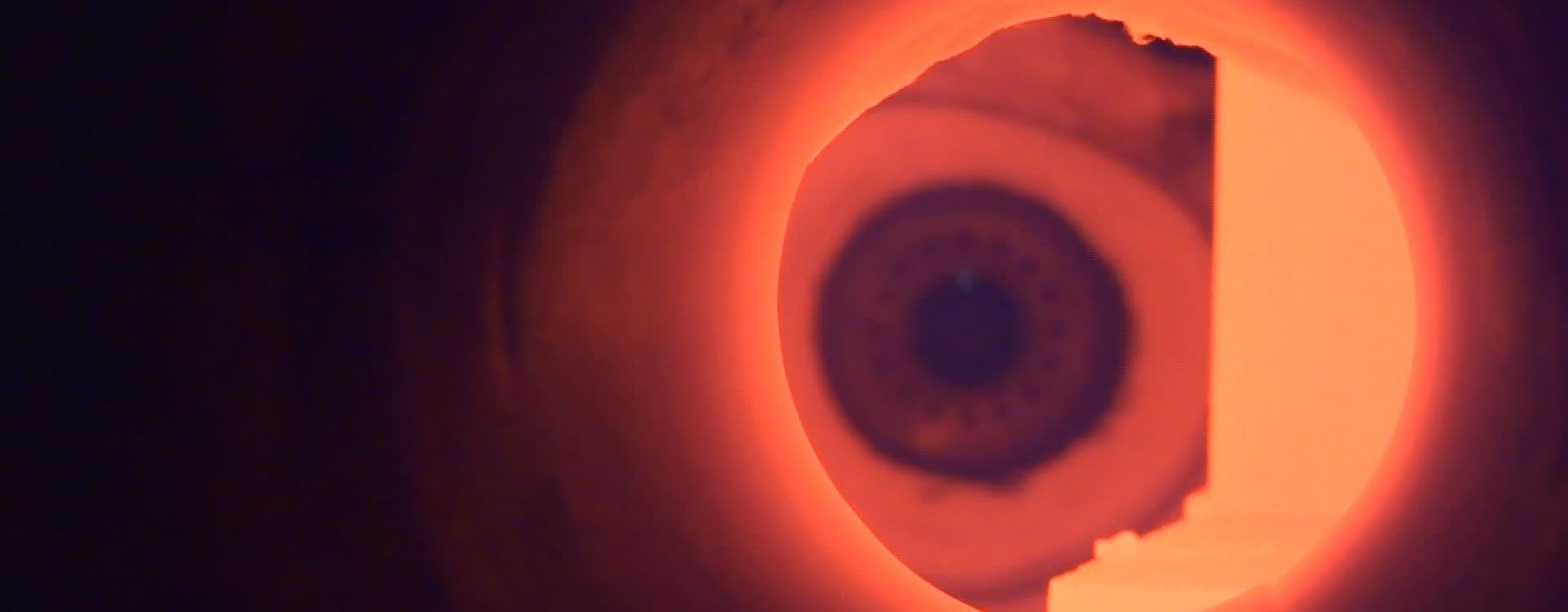

Innovative burner technology: the ECOBURN FL in focus

Efficient and eco-friendly solutions for heat treatment.

The drive to reduce emissions is playing an ever-increasing role in industrial heat treatment, and EBNER is setting new standards in this effort with the introduction of innovative technologies. EBNER innovation can be particularly seen in the ECOBURN FL burner, which stands out due to its high efficiency and extremely low emissions.

In the following interview, EBNER’s Peter Seemann (Senior Principal Expert) and Michael Koller (Senior Product and Business Developer Customer Services) spoke about the advantages provided by ECOBURN FL burners and the applications they are suited for.

What measures has EBNER taken to comply with legal limits on emissions values, as well as other environmental regulations?

Seemann: The EBNER ECOBURN 175 kW burner was specially modified to allow combustion without a flame. This technology provides the lowest possible NOx emissions, while also complying with the most stringent environmental regulations. The only constraint is that, for the technology to be efficiently employed, the minimum furnace temperature must be above 750 °C.

What makes this system so innovative?

Koller: The stand-out feature of the ECOBURN FL is its ability to flexibly regulate its performance. In contrast to many standard burners, which can only be switched on or off, this technology allows the output to be continuously adjusted. This not only optimizes energy consumption but also improves operational stability.

How efficient is an ECOBURN FL in comparison to classic “flamed” burners? Are there measurable advantages?

Seemann: A significant advantage provided by ECOBURN FL is the reduced thermal load on other facility components, and the elimination of temperature peaks extends component service life as well. Furthermore, operation is simplified, as it is only necessary to monitor the furnace temperature. This reduces the susceptibility of the facility to malfunctions.

Which EBNER facilities have already had ECOBURN FL burners installed in them?

Koller: ECOBURN FL burners have already been successfully installed in bell annealers, vertical bright annealing lines and hardening and tempering lines. Thanks to their flexibility and efficiency, they have contributed significantly to the optimization of industrial heat treatment processes.

The bottom line:

An ECOBURN FL is an impressive demonstration of how modern burner technology can contribute to reducing emissions and increasing the efficiency of industrial facilities. With its ability to flexibly regulate output and the reduced thermal load it places on components, the burner is setting new standards in the heat treatment industry – underscoring EBNER’s innovative strength in the field of low-emission industrial furnaces and combustion systems.