Sustainability as a competitive advantage

EBNER Industrieofenbau | Sascha Eppensteiner, Vice President Product Management

Sustainability as a competitive advantage: why it is beneficial to invest in GREENBAFx®

Sustainability is still considered a cost factor in many places – yet it has long since become a strategic success factor. At a time when regulatory requirements are increasing, emission certificates are becoming more expensive, and customers are increasingly demanding climate-friendly materials, the steel industry is also under pressure to fundamentally change its processes.

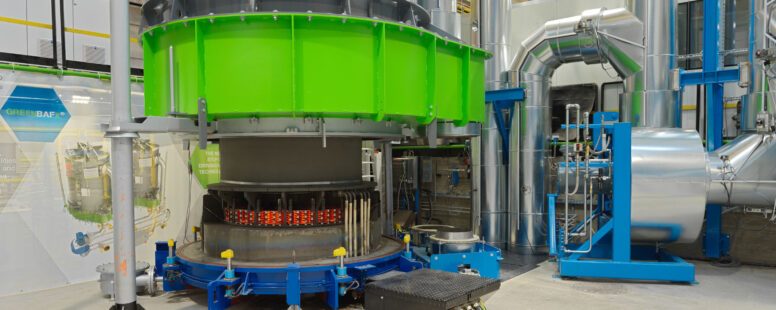

At the heart of this transformation are technologies that avoid emissions, use energy efficiently, and are economically viable at the same time. One of these is GREENBAFx® – a next-generation bell furnace system that operates emission-free and saves up to 30% energy.

In this interview, Sascha Eppensteiner explains why sustainable solutions such as the GREENBAFx® offer not only ecological but also clear economic advantages, what challenges exist in the transition, and why investments in green technologies will determine the competitiveness of entire industries in the future.

Sustainability is often seen as a cost factor – in your opinion, why is this approach short-sighted?

A short-term approach views sustainability as a cost factor, as it requires investment and renewable energies are still more expensive than the fossil fuel alternatives.

Over the long term, however, the initial investment costs are of secondary importance. Across the service life of a facility, operating costs actually make up the majority of the expense.

This is exactly where a targeted investment can generate a lasting competitive advantage – if the investment is made in sustainable technologies that significantly increase energy efficiency and keep operating costs low.

What role does the transition to sustainability play in the global steel industry?

The transition to sustainability is playing a crucial role in the global steel industry, as the sector traditionally consumes a large amount of energy and has significant high emissions.

The steel industry is currently undergoing a profound transformation that is leading to more sustainable production methods, with a goal of drastically reducing or eliminating emissions.

The movement toward sustainability is a powerful driver of innovation, as the necessary technologies are only partially available on the market. At EBNER, our goal is to change this. We are therefore constantly working on new, innovative technologies and developments for a sustainable transformation in the steel industry.

In what way is GREENBAFx® a sustainable solution for heat treatment?

The elimination of CO2 and NOx emissions, the extremely high energy efficiency, the significant energy savings provided by the heat exchange system and the simplification of operations provided by the process bell are revolutionary solutions for heat treatment at a bell annealer facility.

Can zero-emission processes lower operating costs over the long term?

Yes. The most leverage is achieved when zero-emission processes are paired with processes that are highly energy efficient.

What importance do CO₂ savings have to the competitiveness of steel manufacturers?

In carbon-intensive industries, as for example the steel industry, emissions certificates are drivers of product costs.

If processes can be altered in such a way that no CO₂ or only small amounts of CO₂ are emitted, significantly fewer certificates are required for the overall process. This directly addresses a significant cost factor, improving competitiveness.

What advantages are there to producing with a GREENBAFx®?

An emphasis has been placed on maximizing energy efficiency, eliminating emissions and simplifying operating sequences.

The electric heating system integrated into the workbase transfers thermal energy directly to the charge, eliminating “detours” and minimizing heat loss.

As there is no combustion in this type of heating system, CO2 and NOx emissions are completely eliminated.

Thermal energy collected during the cooling phase can be exchanged between workbases and used to preheat a cold charge stack. This can provide savings of up to 30 % of the energy required for the entire heat treatment cycle.

A process bell, which replaces the traditional heating bell, cooling bell and inner cover, is used throughout the entire process and does not need to be exchanged. The process is fully automated, and requires no manual interventions.

The reduced overshoot temperature of the heat-bearing gas and the high convection within the process bell also provide technological advantages, such as improved temperature distribution in the charge stack and a reduced amount of edge overheating.

Do you see an increasing demand for zero-emission product solutions among customers?

Absolutely. The demand for zero-emission solutions is a major issue, both when considering investing in a new facility and when planning the modernization of an existing facility.

Are there any challenges to face when switching to sustainable heat treatment?

The change from conventional, gas-fired processes to a zero-emission approach brings many technical, commercial and infrastructure-related challenges, particularly at heat treatment facilities.

From a technical point of view, the required power density must be provided. It is difficult for standard electric heating system designs to provide the same output densities as gas-fired heating systems, particularly when high temperatures are required.

On the commercial side the level of investment that is required can be challenging, as it tends to be capital-intensive. Renewable energies also tend to be more expensive than fossil fuels. This underlines the importance of thinking ahead when making such an investment, and of investing in systems that keep future operating costs low.

The challenges associated with infrastructure should also not be ignored. The electrification of the processes requires high connected loads, meaning that investments in power supplies must also be made.

How does EBNER support companies that are implementing sustainable technologies?

For the decarbonization of downstream processes, which include heat treatment, EBNER is developing a number of sustainable technologies for zero-emission process heating and increased energy efficiency.

One of these solutions is GREENBAFx®, the next generation of bell annealer facilities.

Others include carbon-neutral heating solutions like special electric heating systems for high-performance applications, hydrogen burner technology, energy exchange systems and more.

Do you believe that investing in sustainable technologies will be a decisive factor for remaining competitive in the future?

Yes, it will provide a decisive competitive advantage.

Across the life cycle of a facility, operating costs make up over 85 % of its total cost. This is the place to start, both because it allows the greatest possible leverage to be applied and because it will allow customers to stay one step ahead of their competition.