EBNER GROUP Blog

Innovation, Technology, Sustainability and People.

Welcome to the EBNER GROUP Blog!

Let’s take a deep dive into the world of innovation, talk about sustainability and provide exciting insights behind the scenes of our international EBNER GROUP. Find out more about our latest technologies, projects and success stories – from groundbreaking developments in the industry to the people who make them possible. Stay informed about current topics, events and news from all EBNER GROUP companies.

Latest News

Georg Gattringer in our Employee Interview

Georg Gattringer has been part of the EBNER family for over 25 years. From apprentice to EVP Production, he has gone through many stages – with exciting challenges, international assignments and a great passion for technology and teamwork. In this interview, he talks about his varied day-to-day work, what motivates him and what advice he has for applicants.

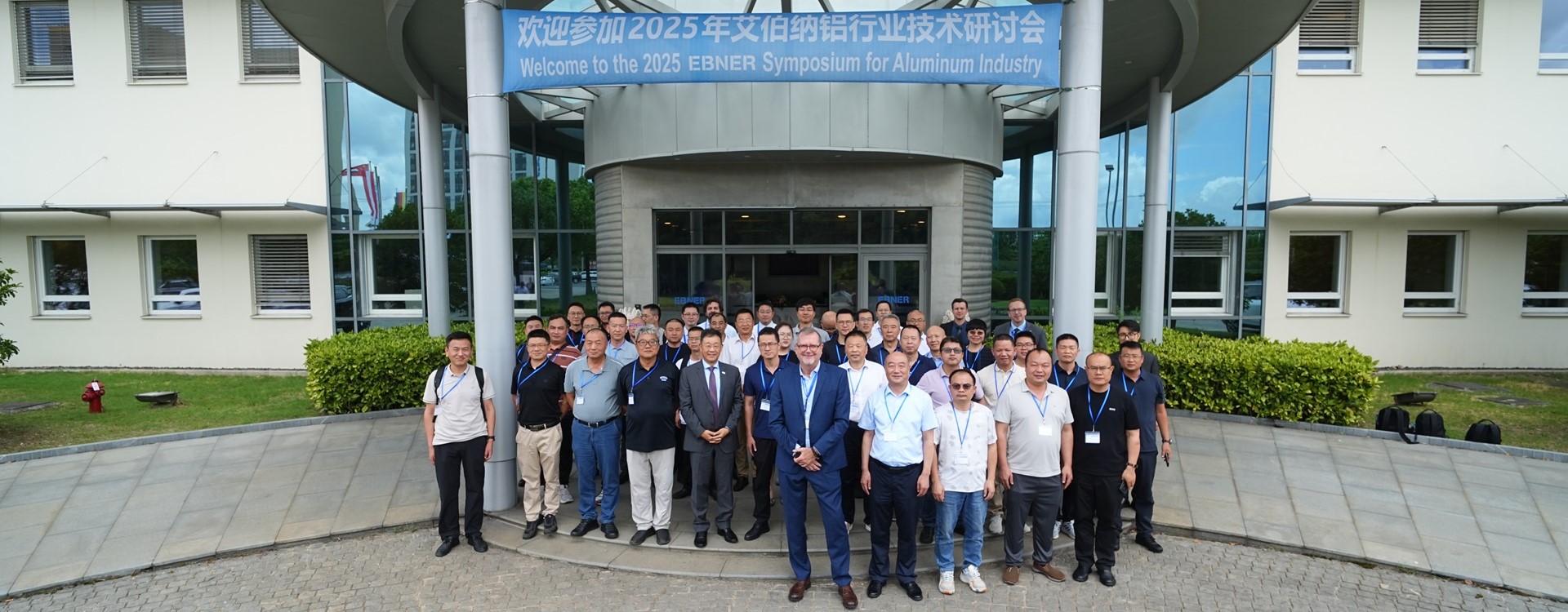

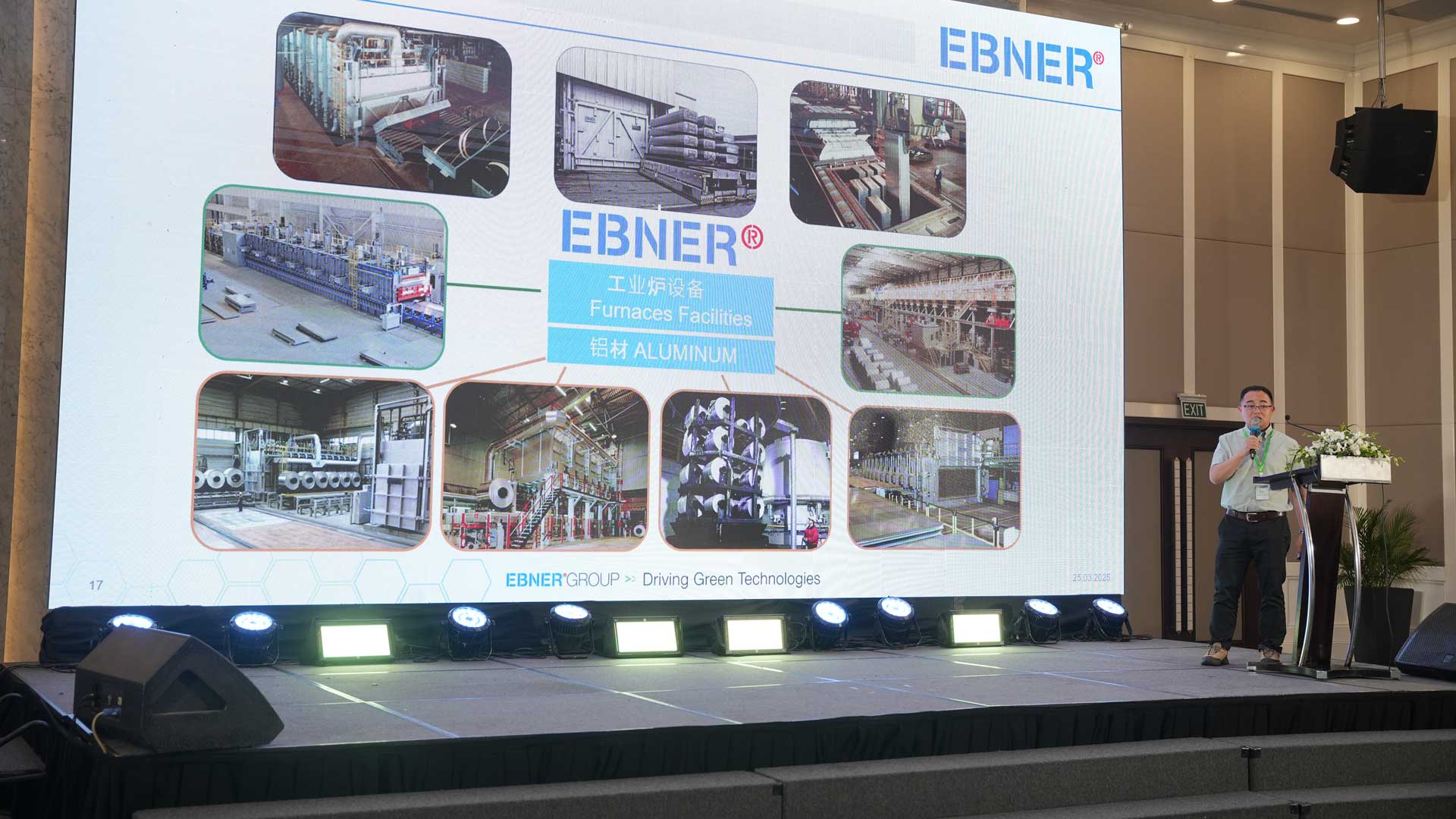

EBNER Symposium for Aluminum Industry

From July 7 to 8, EBNER China hosted a high-profile technology symposium for the aluminum industry. Industry experts from Southeast Asian agencies, customers and Chinese companies came together to discuss technological trends and solutions for aluminum processing.

“A nose for science” nook for Kindergarten Alkoven

Following the successful implementation of three “A Nose for Science” nooks in Leonding and Wilhering, the EBNER GROUP continues its commitment to early childhood education and the promotion of scientific discovery. The fourth nook has now opened at the municipal kindergarten in Alkoven.

Driving Green Technologies

Responsibility for the future. With our sustainable solutions, we are driving decarbonization in the industry.

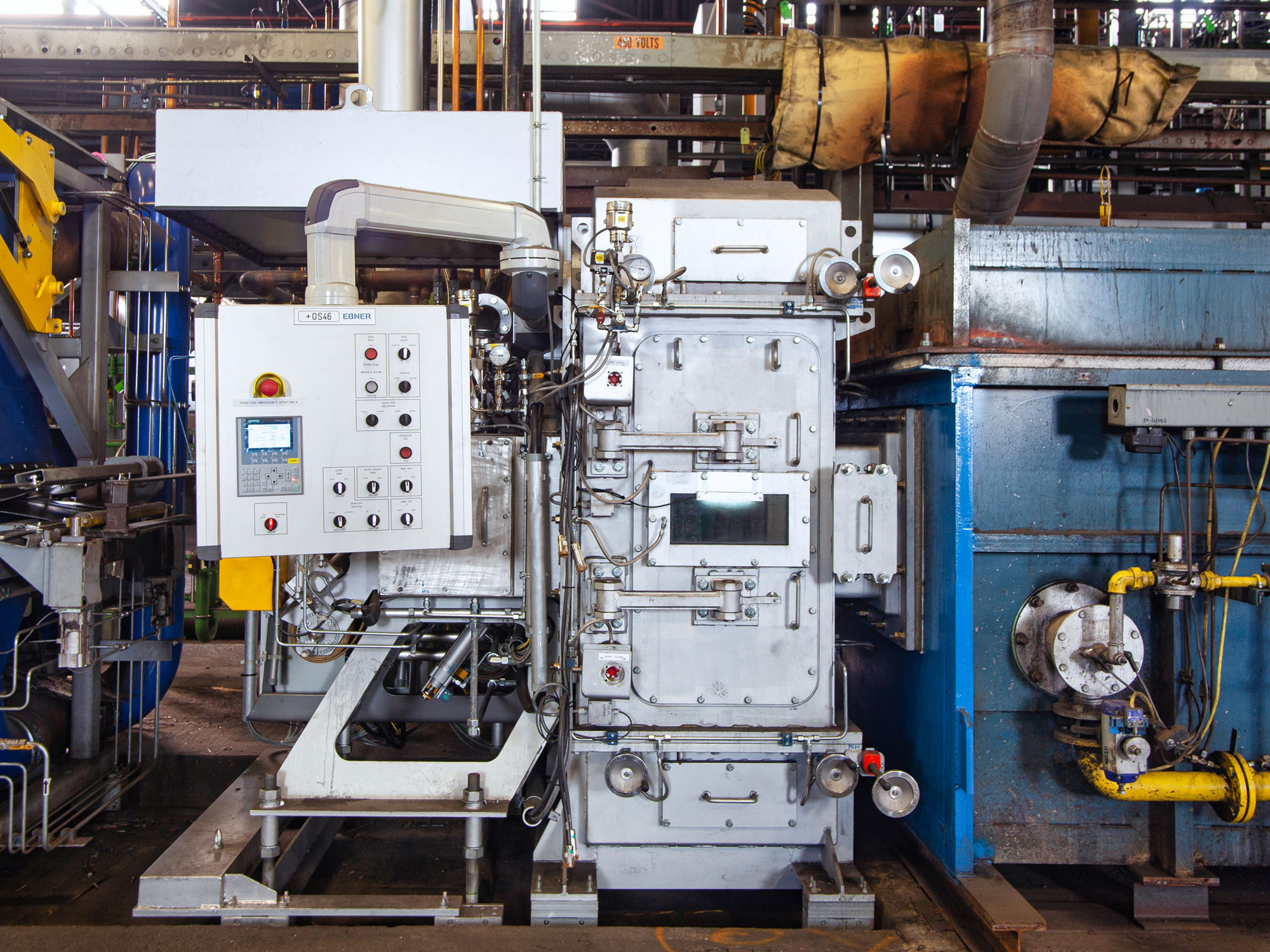

ECOBURN FL in focus

In the following interview, EBNER’s Peter Seemann (Senior Principal Expert) and Michael Koller (Senior Product and Business Developer Customer Services) spoke about the advantages provided by ECOBURN burners and the applications they are suited for.

Sustainable heat treatment

Burner technologies play a central role in industrial heat treatment – whether in terms of efficiency, emissions or an ability to be adapted to alternative fuels. For decades, EBNER has been developing innovative burner solutions for heat treatment furnaces, constantly raising the bar for the rest of the industry.

GREENBAFx

HICON/H2® bell annealers have been successfully operating for decades. Continuous development has increased their performance even as it has lowered costs, allowing the industry to take decisive steps forward in both quality and economy.

More News

Employee Interview – Doris Atzmüller

As Head of the Legal Department at EBNER, Doris and her team ensure that everything in the international group of companies is on a solid legal footing. In this interview, Doris talks about her varied working day, exciting contract negotiations in China, her passion for structure – and why openness and new ideas are particularly valued at EBNER.

Exploring New Opportunities in the Non-Ferrous Metals Industry

On March 24-27, 2025, representatives from EBNER Group—Mr. Zhang Licheng, Senior Sales Manager of HAZELETT, and Mr. Rao Guoyu, Senior Sales Manager of EED—visited Vietnam to participate in the “China-Vietnam Non-Ferrous Metals & Application Industries Forum.”

Get the Lead Out.

Blue Blade Steel´s quantum leap. “Get the lead out!” – This idiom is believed to have originated during World War II and was used to signal soldiers to drop their equipment and ammunition, enabling them to be able to move quicker in certain situations.

Being smart in retrofit.

The steel and aluminum industries are facing unprecedented challenges: rising energy costs, stricter sustainability regulations, global competition, cyber threats and a shrinking talent pool. In this environment, the most competitive companies are those that implement digital technologies quickly and effectively. This is exactly the area in which existing facilities and digital retrofits can form an extremely effective pairing.

CASTHOUSE (R)EVOLUTION CENTER

We are your casthouse for special alloys and individual demands. The Casthouse (R)Evolution Center (C-R-C) in Ranshofen, Austria is a full-scale industrial foundry, incorporating a horizontal casting facility operated by HPI and a vertical casting facility operated by Gautschi.

Proven success.

Jiangsu Pacific Precision Forging Co., Ltd., headquartered in Jiangsu Province, China, is a leading company in the metal processing industry that specializes in precise hot forging techniques. Since its founding, the company has earned an excellent reputation through its commitment to the highest quality standards and innovative technological solutions.