EBNER GROUP Blog

Innovation, Technology, Sustainability and People.

Welcome to the EBNER GROUP Blog!

Let’s take a deep dive into the world of innovation, talk about sustainability and provide exciting insights behind the scenes of our international EBNER GROUP. Find out more about our latest technologies, projects and success stories – from groundbreaking developments in the industry to the people who make them possible. Stay informed about current topics, events and news from all EBNER GROUP companies.

Latest News

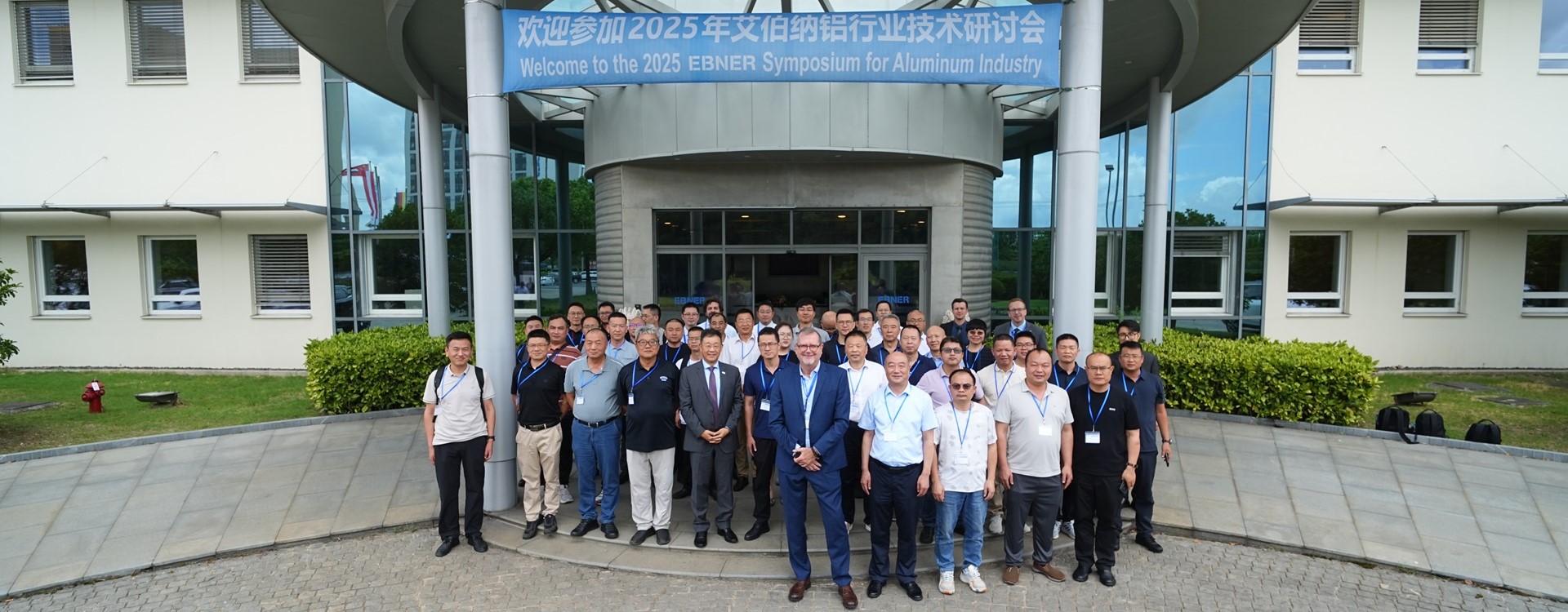

EBNER Symposium for Aluminum Industry

From July 7 to 8, EBNER China hosted a high-profile technology symposium for the aluminum industry. Industry experts from Southeast Asian agencies, customers and Chinese companies came together to discuss technological trends and solutions for aluminum processing.

“A nose for science” nook for Kindergarten Alkoven

Following the successful implementation of three “A Nose for Science” nooks in Leonding and Wilhering, the EBNER GROUP continues its commitment to early childhood education and the promotion of scientific discovery. The fourth nook has now opened at the municipal kindergarten in Alkoven.

From studies to project management: my career path at EBNER

Sebastian Habenschuss joined EBNER in 2023 as a Junior Product Manager alongside his studies. Today, he works as a Sales & Project Manager and manages international projects with technical depth and lots of customer contact. In this interview, he explains what motivates him and why EBNER is the ideal employer for him to develop his career.

Driving Green Technologies

Responsibility for the future. With our sustainable solutions, we are driving decarbonization in the industry.

Sustainable heat treatment

Burner technologies play a central role in industrial heat treatment – whether in terms of efficiency, emissions or an ability to be adapted to alternative fuels. For decades, EBNER has been developing innovative burner solutions for heat treatment furnaces, constantly raising the bar for the rest of the industry.

GREENBAFx

HICON/H2® bell annealers have been successfully operating for decades. Continuous development has increased their performance even as it has lowered costs, allowing the industry to take decisive steps forward in both quality and economy.

Zero-emission steel strip manufacturing

The Korean steel industry places its trust in green technologies from EBNER. In a world where electrical energy and energy storage are constantly increasing in importance, battery manufacturing has become a critical industry.

More News

Furnace modernization.

Logan Aluminum has installed three EBNER pusher furnaces over the years, some of which have been running since the early 90s.

A new era of heat treatment.

Aurubis Stolberg, a leading manufacturer of high-precision copper and copper alloy strip and rod, has modernized its production with a new HICON® bell annealer facility. With this facility, which went into operation in February 2024, the company has taken an important step forward in implementing its decarbonization strategy.

GNA alutech inc. is now fully owned by EBNER GROUP

EBNER GROUP, a global leader for melting, casting and heat treatment solutions for the aluminum industry with the companies EBNER, ETS, EED, Gautschi, TPS, Hazelett, HPI and GNA, has increased their stake in GNA alutech inc. to 100%.

Kindergarten Hainzenbachstraße gets a new EBNER “A Nose for Science” nook.

At the Hainzenbachstraße kindergarten in Leonding, all children can now playfully discover and learn about the fascinating world of technology and science in the “A Nose for Science” nook sponsored by the EBNER GROUP.

STC Heat Treatment Furnaces

A protective atmosphere roller type short cycle annealing furnace, generally referred to as an STC furnace, is primarily used to bright anneal products such as bar, wire, and copper pipe, improving the uniformity of their structures and enhancing their ability to undergo mechanical processing.

A great Honor

David Hazelett receives the Boultinghouse award. The Boultinghouse award is the highest award given by the North American aluminum industry.