GREENBAFx

HICON/H2® bell annealers have been successfully operating for decades. Continuous development has increased their performance even as it has lowered costs, allowing the industry to take decisive steps forward in both quality and economy.

HICON/H2® bell annealers have been successfully operating for decades. Continuous development has increased their performance even as it has lowered costs, allowing the industry to take decisive steps forward in both quality and economy.

An EBNER floater furnace facility sets new standards, even as commissioning is completed ahead of schedule.

The Korean steel industry places its trust in green technologies from EBNER. In a world where electrical energy and energy storage are constantly increasing in importance, battery manufacturing has become a critical industry.

The ATMOSPHEREperfect software module, developed by EBNER for the VISUALFURNACES® control system, significantly contributes to the implementation of a sustainability strategy. The purpose of this module is to significantly reduce the energy consumption and carbon footprint of the heat treatment industry.

The first EBNER HITT bell annealer for high-temperature anneals of grain-oriented (GO) electrical steel strip processes the highest material qualities at Aperam South America Brazil.

As Head of the Legal Department at EBNER, Doris and her team ensure that everything in the international group of companies is on a solid legal footing. In this interview, Doris talks about her varied working day, exciting contract negotiations in China, her passion for structure – and why openness and new ideas are particularly valued at EBNER.

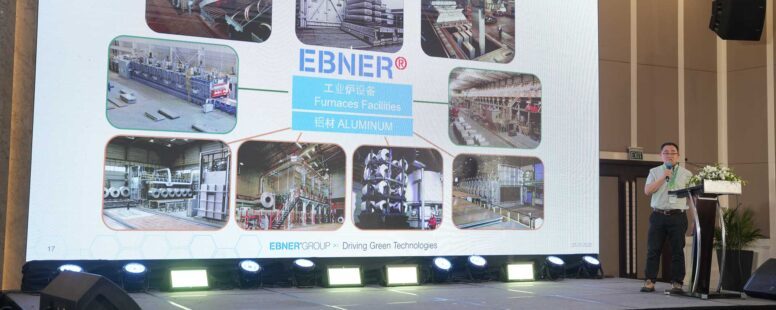

On March 24-27, 2025, representatives from EBNER Group—Mr. Zhang Licheng, Senior Sales Manager of HAZELETT, and Mr. Rao Guoyu, Senior Sales Manager of EED—visited Vietnam to participate in the “China-Vietnam Non-Ferrous Metals & Application Industries Forum.”

My career at EBNER began in commissioning, where I successfully put our facilities into operation for customers around the world. In mid-2022, I switched to Sales and took on the role of Sales Manager. Since December 2024, I have been working as a Sales & Project Manager and contribute my experience from both areas.

I am currently in my 3rd and final year of my apprenticeship. In my 1st year, I worked in the Purchasing department, and since my 2nd year, I have been in the Program and Project Management Office department.

Blue Blade Steel´s quantum leap. “Get the lead out!” – This idiom is believed to have originated during World War II and was used to signal soldiers to drop their equipment and ammunition, enabling them to be able to move quicker in certain situations.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Mapbox. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information